2 – Nylon Fabric Composition

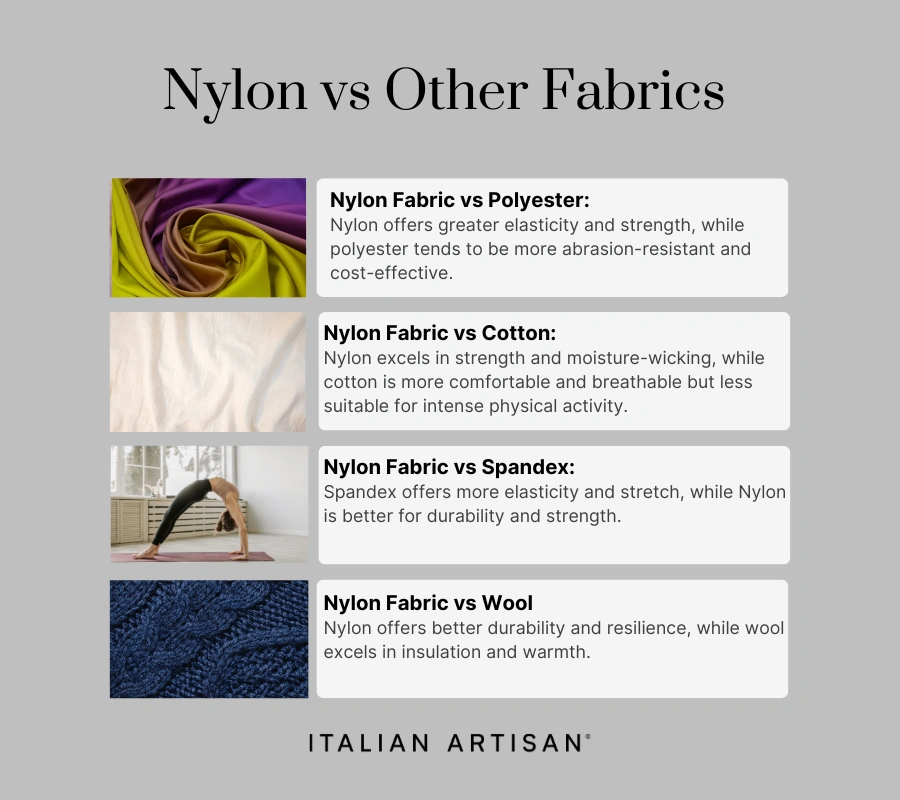

3 – Nylon Fabric vs Other Fabrics

4 – How Nylon Fabric Is Manufactured

5 – Common Uses in Fashion

6 – Understanding the Environmental Impact of Nylon Fabric

7 – Exploring Price Points and Value for Money

8 – Conclusion

9 – FAQs

What is Nylon Fabric?

Nylon fabric is a synthetic textile made from polyamide fibers, first developed by Wallace Carothers and his team at DuPont in the 1930s. It was the world’s first commercially successful synthetic fiber and quickly became a revolutionary material due to its strength, elasticity, and versatility. Nylon is now widely used in everything from clothing and accessories to industrial products. The fabric’s durability, resistance to abrasion, and moisture-wicking properties make it an ideal choice for activewear, sportswear, outerwear, and even luggage.

Key Features of Nylon Fabric:

- Durability: Nylon fabric is known for its strength, making it resistant to wear and tear. This makes it perfect for long-lasting products.

- Elasticity: The fabric has elastic properties, allowing it to retain its shape and provide comfort in activewear.

- Water Resistance: Nylon is naturally water-resistant, which contributes to its use in outerwear and sports gear.

- Lightweight: Despite its strength, Nylon fabric remains lightweight, making it ideal for clothing that requires flexibility and comfort.

The fabric has evolved over time, with improvements in its composition leading to more eco-friendly variants such as recycled nylon. Today, Nylon fabric remains a popular choice across industries due to its versatility and performance.

Nylon Fabric Composition

The composition of Nylon fabric is what gives it its durability, elasticity, and resilience, making it a favored material in both fashion and industrial applications. Unlike natural fibers such as cotton or wool, Nylon is a synthetic polymer made from petroleum-based chemicals. The polyamide fibers that make up Nylon fabric are produced through a polymerization process, where small molecules are chemically bonded together to form long chains. This process gives Nylon its strength, flexibility, and resistance to wear and tear.

Key Components of Nylon Fabric:

- Polyamide Fibers

The core component of Nylon fabric is polyamide, a type of synthetic polymer. The fiber itself is composed of carbon, hydrogen, nitrogen, and oxygen, which are the key elements that form the polyamide chain. This chain structure is what gives Nylon fabric its impressive strength and elasticity. - Fiber Structure

Nylon fibers are created through extrusion, a process where the polyamide material is melted and forced through small holes to form long, continuous strands. The fibers can be textured, spun, or woven into fabric. The resulting Nylon fabric is smooth and shiny, which enhances its aesthetic appeal. Additionally, Nylon fibers are often finely spun, making the fabric soft and comfortable to wear. - Blends with Other Materials

Often, Nylon fabric is blended with other materials to enhance its performance. For example, Nylon may be blended with spandex for added stretch or with cotton to create a fabric that combines breathability and strength. Blends like Nylon and polyester are also common, providing durability, water resistance, and quick-drying properties. - Additives and Treatments

Various additives and finishing treatments can be applied to Nylon fabric to enhance its properties. These can include UV protection, antimicrobial treatments, and water-repellent coatings. These treatments increase the functionality of Nylon fabric, making it suitable for a wide range of applications, from sportswear to outerwear.

How Composition Affects Performance:

- Strength: The polyamide fibers make Nylon fabric extremely strong, allowing it to withstand abrasion, tension, and stress without breaking or fraying.

- Elasticity: Nylon fabric has an inherent elasticity, meaning it can stretch and return to its original shape, making it perfect for activewear and stretch fabrics.

- Moisture Resistance: Nylon’s hydrophobic nature allows it to resist water to a degree, making it ideal for use in outerwear and sportswear.

- Durability: Nylon fabric holds up well to wear and tear, remaining resilient and long-lasting even after repeated use.

The composition of Nylon fabric ensures that it remains one of the most versatile and durable fabrics available, making it suitable for everything from athletic gear to fashion items.

Nylon Fabric vs Other Fabrics

Nylon fabric is often compared to other textiles like polyester, cotton, spandex, and wool, due to its widespread use in fashion, sportswear, and industrial applications. To understand why Nylon fabric is such a popular choice, let’s compare it to some common alternatives.

Nylon Fabric vs Polyester

- Polyester: Like Nylon, polyester is a synthetic fabric made from petroleum-based chemicals. Both are durable, resistant to wrinkling, and moisture-wicking, but there are key differences:

- Nylon is generally stronger and more elastic than polyester, making it better suited for items that require durability and stretch, such as sportswear and outerwear.

- Polyester, however, is typically more resistant to fading and shrinking, and it is slightly more affordable than Nylon.

- Key Difference: Nylon offers greater elasticity and strength, while polyester tends to be more abrasion-resistant and cost-effective.

Nylon Fabric vs Cotton

- Cotton: Cotton is a natural fiber, known for its softness, breathability, and comfort. While Nylon fabric is synthetic, the two fabrics serve different purposes:

- Nylon is stronger, more durable, and better at wicking moisture away from the skin, making it ideal for activewear and outdoor gear.

- Cotton, while more comfortable and breathable, absorbs moisture and tends to retain sweat, which can make it less ideal for sports and high-intensity activities.

- Key Difference: Nylon excels in strength and moisture-wicking, while cotton is more comfortable and breathable but less suitable for intense physical activity.

Nylon Fabric vs Spandex

- Spandex: Spandex, also known as Lycra or elastane, is a stretchable fabric often used in activewear and performance clothing.

- Nylon provides greater durability and strength, while spandex is more elastic and form-fitting.

- In garments like leggings or sports bras, spandex is often blended with Nylon to combine the strength and stretchability of both fabrics.

- Key Difference: Spandex offers more elasticity and stretch, while Nylon is better for durability and strength.

Nylon Fabric vs Wool

- Wool: Wool is a natural fiber that provides excellent insulation and moisture-wicking properties. It is often used in winter wear and cold-weather clothing.

- Nylon is lighter and more durable than wool, making it a better choice for high-performance garments like sportswear and outdoor gear.

- Wool is naturally more breathable and insulating but can be prone to shrinking and pilling.

- Key Difference: Nylon offers better durability and resilience, while wool excels in insulation and warmth.

Key Takeaways:

- Nylon is more durable and lightweight than wool, making it better for performance clothing.

- Nylon outperforms polyester in elasticity and strength, but polyester may be more abrasion-resistant and cost-effective.

- Nylon is stronger and more moisture-wicking than cotton, making it ideal for activewear, while cotton is more comfortable and breathable.

- Nylon is often blended with spandex to combine strength and elasticity in activewear, whereas spandex offers more stretch and form-fitting properties.

How Nylon Fabric Is Manufactured

The manufacturing process of Nylon fabric involves several stages that transform raw materials into a durable, lightweight, and versatile textile. Nylon is a synthetic fiber produced through a process called polymerization, which creates long molecular chains from basic chemical components. These steps ensure that Nylon fabric retains its key properties, including strength, elasticity, and moisture-wicking abilities.

Key Steps in Manufacturing Nylon Fabric:

- Polymerization

The process begins with polymerization, where raw materials such as hexamethylenediamine and adipic acid are combined to create nylon polymer. This chemical reaction results in long molecular chains that form the foundation of the fabric’s strength and durability. - Extrusion

After polymerization, the nylon polymer is melted and pushed through small holes in a machine known as a spinneret. This process forms long, continuous fibers, which are then cooled and hardened to create the nylon filaments that will later be spun into yarn. - Spinning

The cooled nylon filaments are then spun into yarn using a process called spinning. This yarn can be made into continuous filaments or staple fibers, depending on the desired texture of the final fabric. Spinning is critical to determining the thickness and softness of the Nylon fabric. - Weaving or Knitting

The yarn is then woven or knitted into Nylon fabric. The weaving process creates a tightly woven textile that is strong and durable, while knitting creates a more flexible fabric with stretch. Depending on the final use of the fabric, it may undergo different weaving or knitting techniques to achieve the desired texture. - Finishing

After weaving or knitting, Nylon fabric undergoes a finishing process that can include dyeing, water-repellent treatments, and the addition of anti-microbial coatings. Dyeing is done using high-temperature processes or eco-friendly dyeing methods, depending on the manufacturer’s preferences. The finishing treatments enhance the fabric’s performance, providing added strength, comfort, and protection. - Quality Control

Before being sent to the market, Nylon fabric undergoes quality control tests to ensure it meets strength, flexibility, and moisture-wicking standards. These tests assess the fabric’s durability and ensure it can withstand rigorous conditions, particularly for activewear and outdoor gear.

How the Manufacturing Process Affects Performance:

- Strength: The polymerization and extrusion processes give Nylon fabric its inherent strength, making it resistant to abrasion and wear.

- Elasticity: Nylon fibers are naturally elastic, providing the fabric with stretch and flexibility, which is crucial for activewear and sportswear.

- Moisture-Wicking: The structure of Nylon fibers allows them to wick moisture away from the skin, providing comfort during physical exertion by keeping the body dry.

The careful control of each stage in the manufacturing process ensures that Nylon fabric retains its unique qualities, making it ideal for performance garments and outdoor gear.

Produce your fashion collection with us

Common Uses in Fashion

Nylon fabric is widely used in fashion due to its versatility, durability, and performance characteristics. Initially developed as a replacement for silk, Nylon fabric has since become a staple material in sportswear, outerwear, and fashion accessories. Its lightweight and strong properties make it perfect for garments and accessories that require both strength and comfort.

Key Uses of Nylon Fabric in Fashion:

- Activewear and Sportswear:

Nylon fabric is commonly found in sportswear and activewear due to its ability to wick moisture, breathe, and provide flexibility. Nylon is often used in running shorts, leggings, gym wear, and swimwear, where its quick-drying nature and elasticity allow for maximum comfort and performance during high-intensity activities. - Outerwear:

Nylon fabric is widely used in jackets, coats, and windbreakers due to its water-resistant and windproof properties. Nylon’s durability makes it a preferred choice for outerwear that must withstand harsh weather conditions. It is also used in insulated outerwear for added warmth without the added weight, making it ideal for lightweight outer layers. - Bags and Luggage:

Nylon fabric is often used in the production of bags, backpacks, and luggage due to its strength and resilience. It can withstand daily wear and tear, making it perfect for travel gear and everyday carry items. Its lightweight nature also makes it ideal for items that need to be durable yet easy to handle. - Fashion Accessories:

Nylon fabric is also used in fashion accessories such as scarves, hats, and gloves. The fabric’s moisture-wicking and breathability properties make it perfect for garments worn in active or outdoor settings, where comfort and performance are key. - Luxury Fashion:

While Nylon fabric is known for its practicality and performance, it has also been embraced by luxury fashion designers. High-end outerwear, handbags, and footwear have incorporated Nylon for its sleek appearance and functional properties, blending style with functionality.

Why Choose Nylon Fabric in Fashion?

- Durability: Nylon fabric is incredibly strong, making it ideal for items that need to endure wear and tear, such as bags, jackets, and sports gear.

- Lightweight Comfort: Despite its strength, Nylon fabric is lightweight, providing comfort and flexibility in activewear and sportswear.

- Versatility: From swimwear to outerwear, Nylon fabric is versatile enough to be used across many types of fashion, combining both performance and style.

Nylon fabric’s combination of strength, lightweight feel, and moisture-wicking properties makes it a go-to fabric for fashion and functional wear alike.

Understanding the Environmental Impact of Nylon Fabric

While Nylon fabric offers excellent performance, durability, and versatility, its production and disposal come with environmental considerations. As a synthetic fiber, Nylon is derived from petroleum-based resources, raising concerns about its sustainability and its long-term impact on the environment. Understanding the environmental impact of Nylon fabric helps consumers make informed decisions when purchasing products made from this material.

Key Environmental Considerations:

- Non-Biodegradability

One of the major environmental challenges with Nylon fabric is that it is non-biodegradable, meaning it doesn’t decompose naturally in landfills. As a result, Nylon can contribute to long-term waste in the environment if improperly discarded. This is a significant issue for the fashion industry, where fast fashion and discarded garments can lead to significant environmental harm. - Energy-Intensive Manufacturing

The production process of Nylon fabric is energy-intensive, particularly during the polymerization and spinning phases. The raw materials, primarily petroleum-based, require high temperatures and chemical processes to create the fibers, which increases the carbon footprint of the fabric. This contributes to global warming and resource depletion. - Water Usage

Like many synthetic fabrics, Nylon fabric production requires significant water usage, especially in the dyeing and finishing stages. Dyeing processes often require large amounts of water, which, if not properly managed, can lead to water waste and pollution in surrounding areas. - Chemical Treatments

The dyeing and finishing of Nylon fabric often involve the use of harmful chemicals that can be released into the environment. These chemicals, if not properly treated or disposed of, can pollute the air and water, contributing to environmental degradation and toxic waste.

Sustainable Alternatives and Solutions:

- Recycled Nylon:

An increasing number of manufacturers are turning to recycled Nylon (often called nylon 6), which helps reduce the need for virgin petroleum-based resources. By recycling old fabrics, fishing nets, or industrial waste, recycled Nylon reduces the environmental impact of producing new material. - Closed-Loop Systems:

Some companies are adopting closed-loop systems where Nylon fabric is recycled at the end of its life cycle. This process reduces waste and allows the material to be reused in future products, making Nylon fabric more sustainable. - Eco-Friendly Dyeing Methods:

Waterless dyeing and the use of natural dyes are gaining traction as more sustainable alternatives to traditional chemical dyeing. These methods reduce the water and chemical usage during the fabric’s production.

Key Takeaways:

- By choosing sustainable Nylon products and supporting brands that adopt ethical production practices, consumers can contribute to reducing the environmental footprint of Nylon fabric.

- Nylon fabric is non-biodegradable and its production requires significant energy and water, contributing to environmental concerns.

- Advances in recycled Nylon, eco-friendly dyeing, and closed-loop systems are helping mitigate the fabric’s environmental impact.

Exploring Price Points and Value for Money

Durability and Versatility:

While Nylon fabric may have a higher initial cost compared to other basic fabrics like cotton or polyester, its strength and resilience make it a cost-effective investment in the long run. Nylon fabrics tend to last longer, making them a good choice for outdoor gear, activewear, and luggage.

Performance:

The moisture-wicking, breathability, and lightweight qualities of Nylon fabric make it ideal for sportswear and performance wear. The comfort and functional benefits provided by Nylon fabric justify its price for those who need high-performance gear for active or outdoor activities.

Sustainability:

As sustainability becomes an increasing priority for consumers, Nylon fabric made from recycled materials provides great value for those seeking eco-friendly alternatives. Even though recycled nylon may have a slightly higher price than virgin nylon, its environmental benefits make it a valuable investment for those looking to reduce their carbon footprint.

Key Takeaways:

- Recycled nylon provides a sustainable option that offers good value while helping reduce environmental impact.

- Nylon fabric is generally affordable and offers good value for money due to its durability, performance, and versatility.

- The price of Nylon fabric can vary depending on factors such as fiber quality, brand, and finishing treatments.

Conclusion

Nylon fabric is a versatile, durable material known for its strength, elasticity, and moisture-wicking properties. While it’s more expensive than other fabrics like polyester, its long-lasting performance and comfort make it a valuable investment. Innovations in recycled nylon and eco-friendly production are addressing environmental concerns, making Nylon fabric more sustainable. Whether used in activewear, outerwear, or luxury fashion, Nylon fabric offers great value for those seeking high-performance and style.

FAQs

1. What is Nylon fabric?

Nylon fabric is a synthetic textile made from polyamide fibers that are durable, moisture-wicking, and lightweight. It’s commonly used in activewear, sportswear, and fashion accessories.

2. How is Nylon fabric made?

Nylon fabric is produced by polymerizing chemicals like hexamethylenediamine and adipic acid to create long polyamide chains, which are then spun into fibers and woven or knitted into fabric.

3. Is Nylon fabric environmentally friendly?

While Nylon fabric is made from petroleum-based chemicals, recycled Nylon options are available, which reduce its environmental footprint. Eco-friendly production practices, like waterless dyeing, also help minimize impact.

4. Is Nylon fabric strong?

Yes, Nylon fabric is known for its strength and durability, making it resistant to wear and tear. This is why it’s used in sports gear, outerwear, and luggage.

5. How do I care for Nylon fabric?

Nylon fabric is easy to care for. It should be machine washed on a gentle cycle and air-dried. Avoid using fabric softeners as they can reduce its moisture-wicking properties.

6. Is Nylon fabric breathable?

Yes, Nylon fabric is breathable, which helps in moisture control and makes it suitable for activewear and sportswear.

7. Does Nylon fabric shrink?

Nylon fabric is resistant to shrinking, but it’s best to follow the care instructions to maintain its shape and performance.

8. Is Nylon fabric used in luxury fashion?

Yes, Nylon fabric is used in luxury fashion, especially for outerwear, accessories, and high-performance sportswear, offering both style and functionality.

9. How does Nylon fabric compare to polyester?

Both Nylon and polyester are synthetic fabrics, but Nylon is generally stronger and more elastic, while polyester is more abrasion-resistant and tends to be more affordable.

10. Can Nylon fabric be recycled?

Yes, Nylon fabric can be recycled, with increasing efforts to produce recycled Nylon from post-consumer waste, reducing its environmental impact.