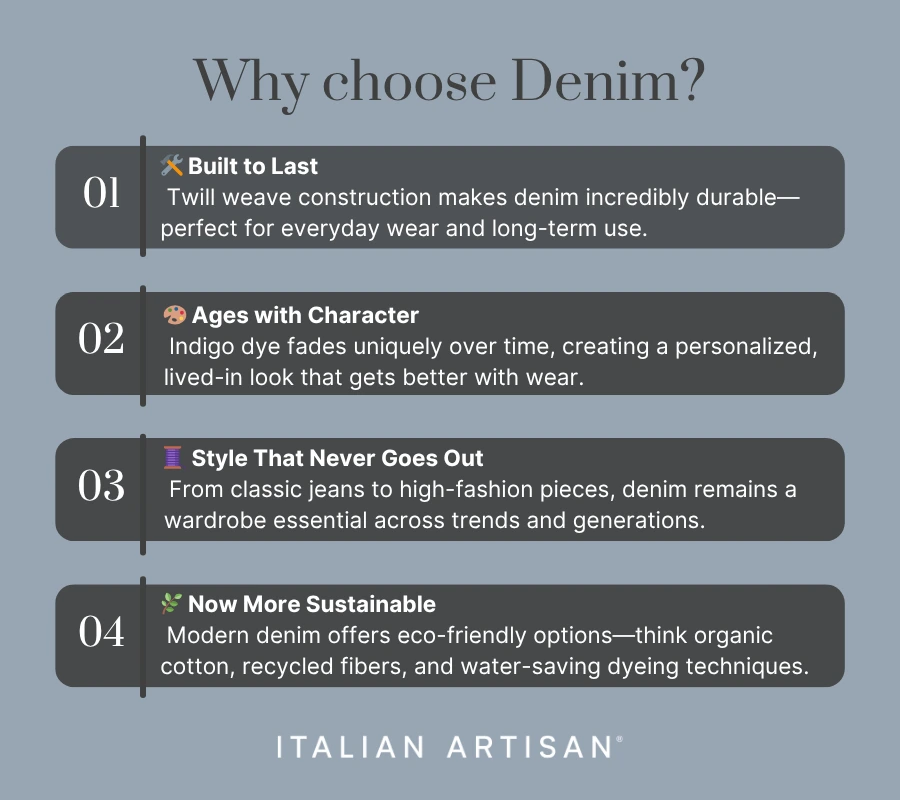

2 – Benefits of Choosing Denim Fabric

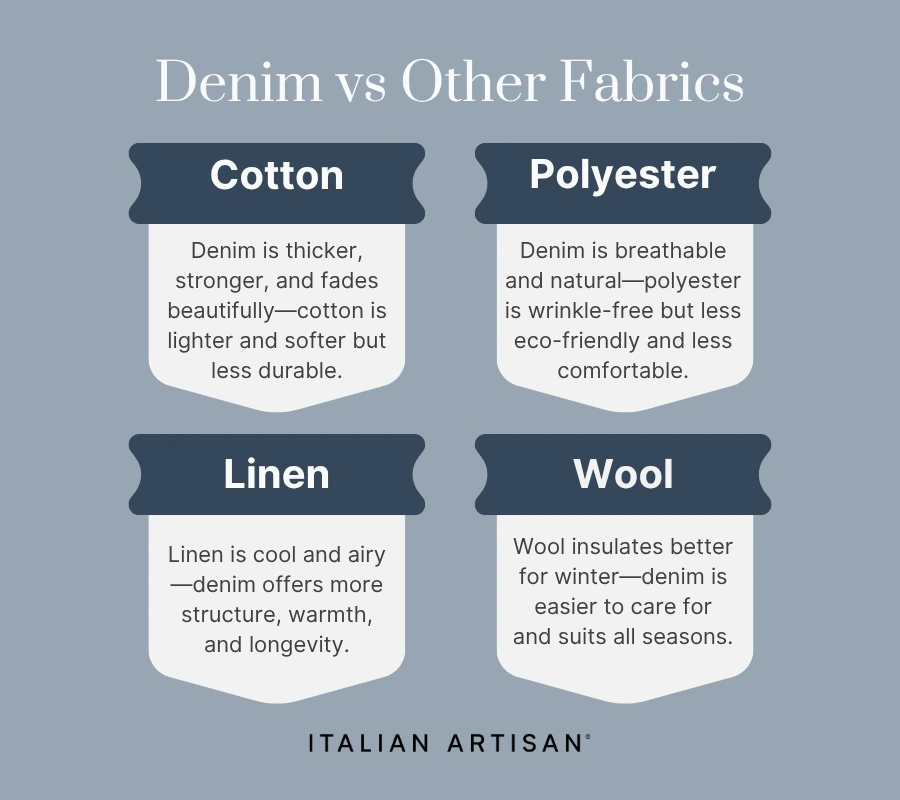

3 – Denim Fabric vs Other Fabrics

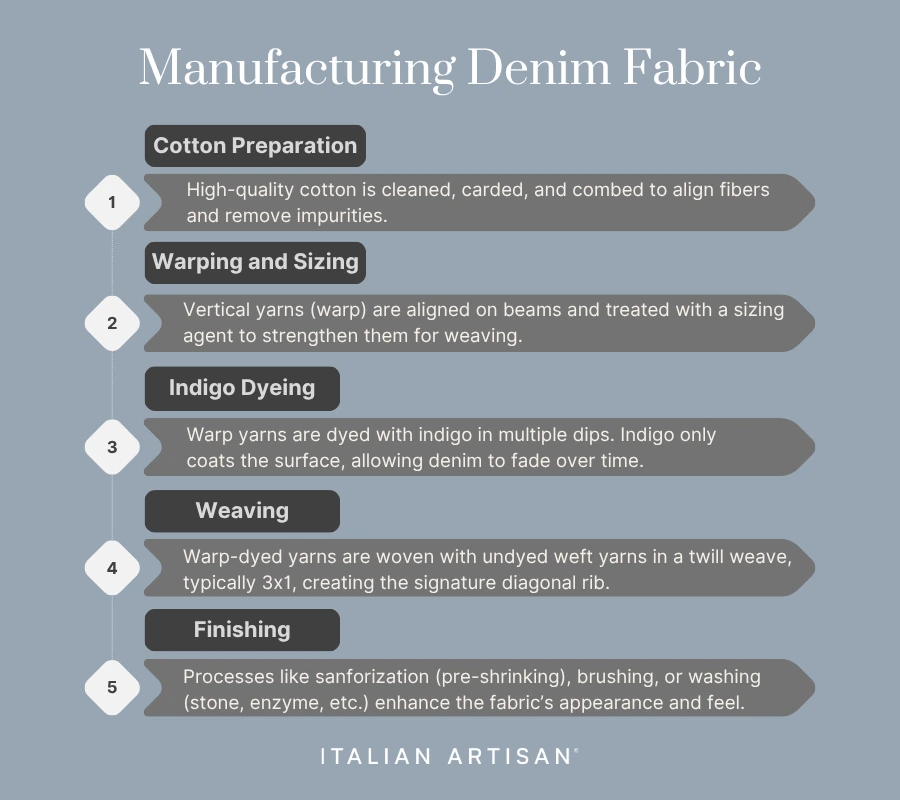

4 – How Denim Fabric Is Manufactured

5 – Common Uses in Fashion

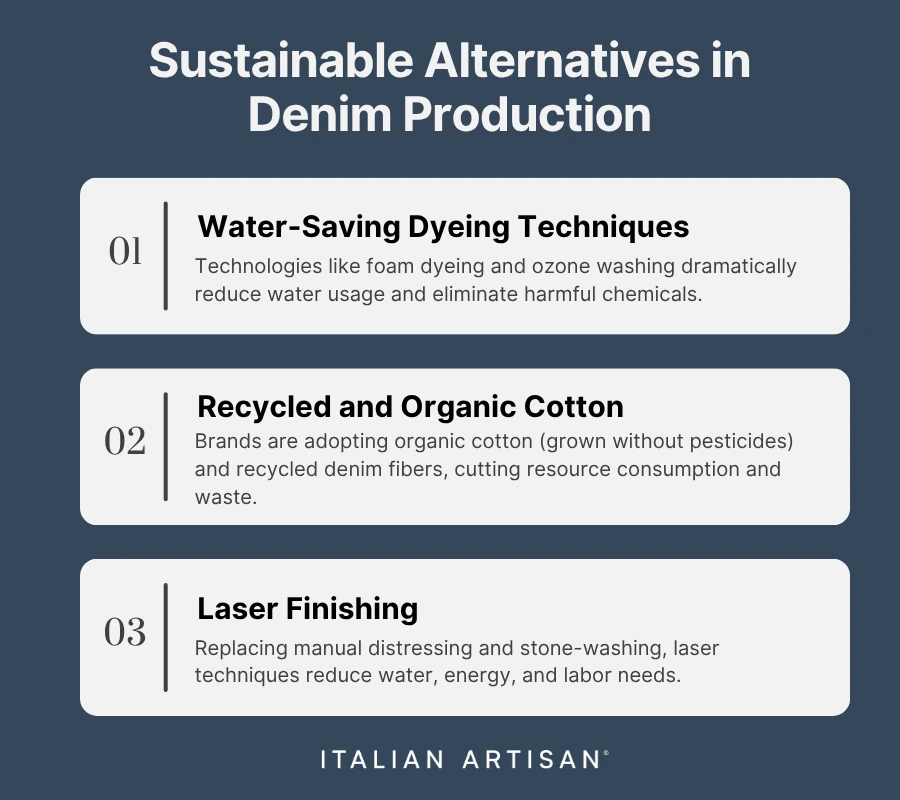

6 – Understanding the Environmental Impact of Denim Fabric

7 – Exploring Price Points and Value for Money

8 – Conclusion

9 – FAQs

What is Denim Fabric?

Denim fabric is a durable cotton twill textile, best known for its use in jeans and iconic workwear. What sets denim apart is its distinct diagonal weave pattern, created by weaving white weft threads under two or more indigo-dyed warp threads. This construction gives denim its signature texture, color contrast (white on the inside, blue on the outside), and long-lasting strength.

Originally developed in the 19th century for miners and laborers due to its ruggedness, denim has since become a global staple in fashion—from everyday casual wear to high-end designer collections. While traditionally made from 100% cotton, modern denim may include stretch fibers like elastane for comfort and flexibility.

Key characteristics of denim include:

- Twill weave structure: Visible diagonal ribs add strength and visual texture.

- Indigo dyeing: Warp yarns are dyed with indigo, fading over time to create unique patterns.

- Versatility: Used in clothing, accessories, and even upholstery.

- Aging beautifully: Fades and softens over time, often improving with wear.

Benefits of Choosing Denim Fabric

Denim fabric offers a unique blend of durability, comfort, and timeless appeal, making it a popular choice across industries—from fashion to interior design. Whether you’re a designer, consumer, or manufacturer, denim provides a range of advantages:

- Exceptional Durability

The tightly woven twill structure of denim makes it highly resistant to wear and tear, ideal for long-lasting garments and workwear. - Timeless Aesthetic

Denim never goes out of style. Its classic look—especially in blue—has remained relevant for over a century, easily adapting to trends without losing its identity. - Versatility

Suitable for jeans, jackets, shirts, dresses, bags, and upholstery, denim fabric can be styled casually or dressed up, depending on the finish and cut. - Comfort Over Time

Denim molds to the wearer’s body, becoming more comfortable with use. Washed or stretch-infused denim can offer a soft, flexible feel from the start. - Aging Gracefully

One of denim’s most admired traits is its ability to fade and develop character over time, creating a unique appearance with every wear. - Breathability

Traditional 100% cotton denim allows good air circulation, making it comfortable to wear in different climates—especially lighter weights. - Low Maintenance

Denim is easy to care for and doesn’t require frequent washing. It’s machine washable and holds up well through repeated use. - Eco-Friendly Options Available

With growing demand for sustainability, many brands now offer organic cotton denim, recycled denim, or denim dyed using water-saving techniques.

Denim Fabric vs Other Fabrics

When choosing a fabric, it’s important to understand how denim compares to other popular materials. Below is a breakdown of how denim stacks up against cotton, polyester, linen, and wool based on key attributes:

- Denim vs Cotton (Plain Weave)

- Denim is woven in a twill pattern, making it more durable and structured than plain-woven cotton.

- Cotton is softer and more breathable initially, while denim becomes more comfortable over time.

- Cotton tends to wrinkle easily; denim holds its shape better.

- Denim fades and gains character with wear, whereas cotton maintains a consistent look.

- Denim vs Polyester

- Denim is a natural (usually cotton-based) fabric, while polyester is synthetic and derived from petroleum.

- Polyester is wrinkle-resistant and quick-drying, but less breathable than denim.

- Denim has a more premium and timeless look; polyester is often used for fast fashion and activewear.

- In terms of sustainability, denim made from organic or recycled fibers is more eco-friendly than polyester.

- Denim vs Linen

- Linen is lightweight and highly breathable—ideal for warm weather.

- Denim is thicker and more robust, making it better for structured garments and cooler climates.

- Linen wrinkles easily and has a casual, airy look; denim maintains form and ages with character.

- Linen has a lower environmental impact, but sustainable denim is catching up with water-saving and eco-dyeing techniques.

- Denim vs Wool

- Wool is warm and insulating—great for winter garments—while denim is better suited for mid-season or layering.

- Denim is easier to care for and machine-washable, while wool often requires dry cleaning.

- Wool can pill or felt over time; denim softens and fades in a desirable way.

- Both are durable , but denim is more versatile in styling across seasons and genders.

How Denim Fabric Is Manufactured

The manufacturing of denim fabric is a detailed process that blends traditional craftsmanship with modern technology. Though it starts like most woven fabrics, denim’s signature look and feel come from its unique dyeing and weaving techniques.

Here’s a step-by-step overview of how denim is made:

1. Cotton Selection and Preparation

- Denim begins with high-quality cotton fibers, typically long-staple cotton for strength and softness.

- The raw cotton is cleaned, carded, and combed to align the fibers and remove impurities.

2. Spinning

- The cotton fibers are spun into yarn using either open-end or ring-spinning methods.

- Ring-spun yarn produces a softer, stronger denim with a vintage texture, while open-end spinning is more economical and produces a more uniform finish.

3. Warping and Sizing

- The yarns intended for the warp (vertical threads) are arranged on large beams.

- They are then coated with a sizing agent (a starch-based solution) to strengthen them for weaving and reduce breakage.

4. Indigo Dyeing

- The warp yarns are dyed using indigo, a dye that only coats the surface of the fibers.

- Unlike other dyes, indigo doesn’t fully penetrate the fiber, which is why denim fades in a distinctive way over time.

- The dyeing is usually done through rope dyeing or slasher dyeing:

- Rope dyeing: yarns are twisted into ropes and repeatedly dipped into indigo baths.

- Slasher dyeing: flat yarns pass through dye baths in sheet form—faster but less intense.

5. Weaving

- Denim is woven on shuttle looms (for selvedge denim) or projectile/air-jet looms (for mass production).

- The dyed warp yarns are woven with undyed weft (horizontal) yarns using a 3×1 twill weave, where one weft thread passes under three warp threads.

- This weave gives denim its diagonal rib pattern and rugged texture.

6. Finishing

- After weaving, the raw denim is finished to enhance its usability and look:

- Sanforization: A pre-shrinking process to reduce shrinkage during consumer washing.

- Brushing or singeing: Removes loose fibers from the surface.

- Coating or washing: May be applied to give the denim a specific color, finish, or feel (e.g., stone-washing, enzyme washing).

7. Cutting and Sewing (Final Garment Stage)

- Once the denim fabric is produced, it is cut and sewn into garments like jeans, jackets, or accessories.

- At this stage, manufacturers may also add distressing, fading, or embellishments for stylistic purposes.

Produce your fashion collection with us

Common Uses in Fashion

Denim’s blend of durability, comfort, and timeless appeal makes it a staple across various fashion categories. Its adaptability allows designers to reimagine the fabric in both classic and contemporary styles.

Most common applications include:

- Jeans

The most iconic use of denim—available in countless cuts (skinny, straight, wide-leg, bootcut) and washes, from raw to distressed. - Jackets

Denim jackets are a versatile outerwear choice, offering structure and a casual-cool look across seasons. - Shirts & Blouses

Lightweight denim or chambray is used for button-down shirts, blending a relaxed vibe with a polished feel. - Dresses & Skirts

From fitted mini skirts to flowy midi dresses, denim brings structure and edge to womenswear pieces. - Shorts

Cut-off or tailored, denim shorts are warm-weather essentials with endless styling options. - Overalls & Jumpsuits

Originally workwear, now a fashion-forward choice in both casual and statement designs. - Accessories

Denim is used for hats, belts, tote bags, and even shoes, adding texture and personality to everyday looks. - Streetwear & High Fashion

Designers reinterpret denim with bold silhouettes, embellishments, and hybrid garments, proving its relevance on runways and in urban style.

Understanding the Environmental Impact of Denim Fabric

Denim is one of the most widely produced fabrics in the world, but its traditional manufacturing process has raised environmental concerns—particularly around water use, chemical treatments, and energy consumption. However, the industry is rapidly evolving toward more sustainable practices.

Key environmental challenges:

- High Water Consumption

Traditional denim dyeing and finishing can use up to 10,000 liters of water per pair of jeans, including cotton cultivation and washing processes. - Chemical Use

Conventional indigo dyeing involves synthetic dyes and chemical fixatives, which can lead to water pollution if not treated properly. - Energy and Emissions

Spinning, weaving, and finishing are energy-intensive stages, often powered by fossil fuels, contributing to carbon emissions. - Waste Generation

Fast fashion leads to overproduction and discarded denim garments, many of which are not biodegradable if blended with synthetic fibers.

Positive developments and sustainable alternatives:

- Water-Saving Dyeing Techniques

Technologies like foam dyeing and ozone washing dramatically reduce water usage and eliminate harmful chemicals. - Recycled and Organic Cotton

Brands are adopting organic cotton (grown without pesticides) and recycled denim fibers, cutting resource consumption and waste. - Laser Finishing

Replacing manual distressing and stone-washing, laser techniques reduce water, energy, and labor needs.

Exploring Price Points and Value for Money

Denim fabric comes in a wide range of price points, influenced by factors such as material quality, weaving method, dyeing technique, and sustainability practices. Understanding what drives these differences helps consumers and brands make more informed purchasing decisions.

Key factors affecting denim prices:

- Fabric Quality

- Ring-spun or selvedge denim (usually woven on shuttle looms) tends to be more expensive due to its premium feel and durability.

- Cheaper options use open-end spinning or blends with synthetic fibers, which are less breathable and wear out faster.

- Dyeing and Finishing Techniques

- Traditional indigo rope dyeing and eco-friendly finishes increase costs but offer better aging and lower environmental impact.

- Cheaper jeans often rely on less sustainable dyeing methods and harsh chemical treatments.

Value for Money: What to Consider

- Longevity: High-quality denim lasts for years, often becoming more comfortable and stylish with time.

- Comfort and Fit: Premium denim molds to the body and retains shape, reducing the need for frequent replacements.

- Environmental Impact: Spending more on sustainable denim supports eco-conscious practices and often results in less waste.

- Style Versatility: A well-made pair of jeans or a denim jacket can be worn across seasons and occasions—maximizing cost per wear.

Conclusion

Denim fabric is far more than just a wardrobe staple—it’s a textile with deep roots, distinct properties, and lasting cultural relevance. From its durable twill weave and signature indigo fade to its growing role in sustainable fashion, denim offers both style and substance. Whether chosen for its comfort, versatility, or timeless appeal, denim remains a smart, enduring choice in both fashion and function.

FAQs

1. What is denim fabric made of?

Denim is typically made from 100% cotton, though modern versions may include elastane or polyester for added stretch and durability.

2. What makes denim different from other cotton fabrics?

Denim is woven in a twill weave with indigo-dyed warp threads, creating a durable, diagonal-ribbed texture and its classic two-tone appearance.

3. Why does denim fade over time?

Indigo dye only coats the outer layer of the yarn, so with wear and washing, the inner white fibers begin to show, creating a natural fade.

4. What is selvedge denim?

Selvedge denim is woven on traditional shuttle looms, producing a clean, tightly bound edge that prevents fraying and is considered a mark of premium quality.

5. Is denim fabric sustainable?

Traditional denim production has a high environmental impact, but sustainable alternatives use organic cotton, recycled fibers, and water-saving dyeing techniques.

6. How should I wash denim?

Wash denim inside out in cold water to preserve color and shape. Avoid frequent washing to maintain fabric integrity and reduce environmental impact.

7. Can denim be worn year-round?

Yes. Lightweight denim is great for warmer weather, while heavier denim works well in cooler months. Layering also makes it a versatile year-round option.

8. What is raw denim?

Raw denim is unwashed and untreated after dyeing and weaving. It develops personalized fades over time based on the wearer’s habits.

9. Is denim suitable for formal wear?

While traditionally casual, dark-wash or tailored denim can be styled for smart-casual or business-casual looks, especially when paired with structured pieces.

10. How long does denim last?

High-quality denim can last for years, even decades, especially when properly cared for. It often becomes softer and more visually appealing with time.