2 – Benefits of Choosing Crepe Fabric

3 – Crepe Fabric vs Other Fabrics

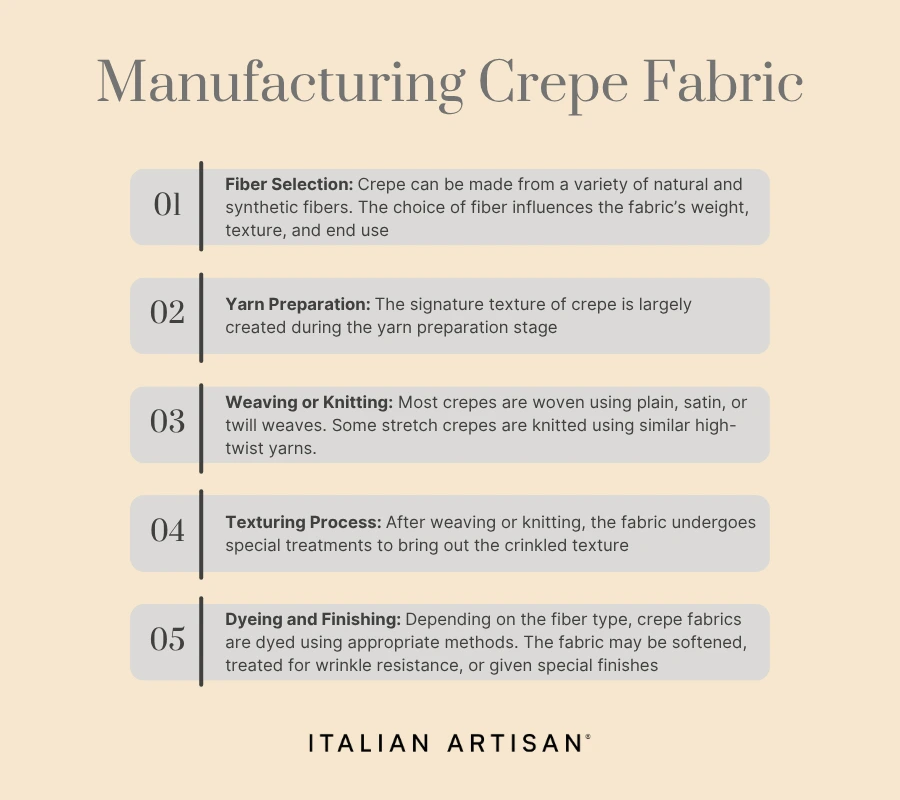

4 – How Crepe Fabric Is Manufactured

5 – Common Uses in Fashion

6 – Understanding the Environmental Impact of Crepe Fabric

7 – Exploring Price Points and Value for Money

8 – Conclusion

9 – FAQs

What is Crepe Fabric?

Crepe fabric is a versatile, textured textile known for its distinctive crinkled or grainy surface, achieved through unique weaving or finishing techniques. Lightweight and often slightly stretchy, crepe is prized across both fashion and interior design for its fluid drape and elegant appearance. But what truly defines crepe is not a single fiber or method—it’s a finish. In fact, crepe refers to the texture rather than the material, meaning it can be made from natural fibers like silk, cotton, and wool, or synthetic ones like polyester and rayon.

To understand what crepe fabric is, it helps to break it down into key characteristics:

- Texture: Its signature wrinkled or pebbled surface is created by tightly twisting yarns before weaving or by chemical treatments that shrink the fabric in irregular ways.

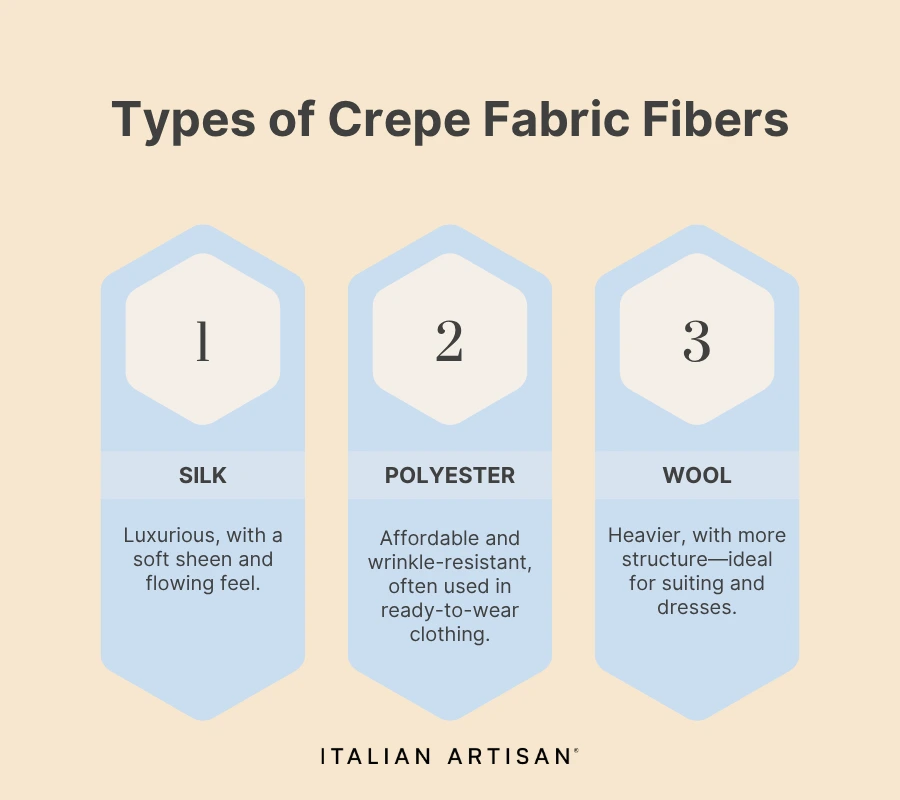

- Fiber Composition: There is no single “crepe fiber.” Common types include:

- Silk crepe: Luxurious, with a soft sheen and flowing feel.

- Polyester crepe: Affordable and wrinkle-resistant, often used in ready-to-wear clothing.

- Wool crepe: Heavier, with more structure—ideal for suiting and dresses.

- Weave Types: Crepe can be woven in plain, satin, or twill structures, depending on the desired weight and drape.

- Appearance & Feel: It ranges from matte to glossy and from soft and pliable to crisp and structured.

Benefits of Choosing Crepe Fabric

Crepe fabric stands out not just for its unique texture but also for the practical and aesthetic advantages it offers. Whether used in fashion, interior design, or formalwear, its benefits make it a popular choice across many applications. Here are the key reasons why crepe fabric is highly valued:

- Elegant Drape

Crepe’s fluidity and movement make it ideal for garments that need to fall gracefully on the body, such as dresses, blouses, and scarves. - Versatility in Design

Available in different weights and finishes—from matte to glossy—crepe works well for both casual and formal pieces. It can be tailored into structured suits or flowy gowns with equal success. - Wrinkle Resistance

Thanks to its naturally crinkled texture, crepe fabric resists visible wrinkling, making it a low-maintenance option ideal for travel or all-day wear. - Comfort and Breathability

When made from natural fibers like silk, cotton, or wool, crepe provides excellent breathability and is comfortable to wear in various climates. - Lightweight Yet Opaque

Many crepe fabrics offer a great balance between being lightweight and providing sufficient coverage—perfect for layering without transparency issues. - Wide Range of Fiber Options

Crepe is not limited to one material: it’s available in silk for luxury, polyester for affordability and durability, or wool for structure and warmth. - Excellent for Draping and Tailoring

Its structure allows for precise tailoring, while still maintaining a graceful flow, making it ideal for professional, bridal, or evening wear. - Minimal Shine for a Sophisticated Look

Unlike satin or chiffon, crepe often has a matte or semi-matte finish that gives it a more refined and timeless appeal.

Crepe Fabric vs Other Fabrics

Crepe fabric stands out for its textured surface, graceful drape, and versatility. Here’s how it compares to other commonly used fabrics:

- Crepe vs Cotton

- Crepe: Wrinkle-resistant, drapes beautifully, elegant finish

- Cotton: Breathable and soft but prone to wrinkling and less fluid in drape

- Crepe vs Chiffon

- Crepe: Opaque, easier to handle, matte or slight sheen

- Chiffon: Sheer, delicate, lightweight with a soft shimmer

- Crepe vs Satin

- Crepe: Matte, textured, less clingy

- Satin: Smooth, glossy, ideal for formalwear but shows wrinkles more

- Crepe vs Linen

- Crepe: Soft drape, minimal wrinkles, adaptable year-round

- Linen: Crisp, breathable, highly prone to creasing—best for summer

- Crepe vs Silk

- Crepe: Can include silk, but more structured and matte

- Silk: Luxuriously soft and shiny, but delicate and often high-maintenance

How Crepe Fabric Is Manufactured

Crepe fabric’s distinctive crinkled texture isn’t the result of just one technique or material—it’s a product of careful manipulation of yarns, weaving methods, and finishing processes. Here’s a step-by-step overview of how crepe fabric is typically manufactured:

1. Fiber Selection

Crepe can be made from a variety of natural and synthetic fibers. The choice of fiber influences the fabric’s weight, texture, and end use:

- Natural fibers: Silk, wool, cotton.

- Synthetic fibers: Polyester, rayon, acetate.

2. Yarn Preparation

The signature texture of crepe is largely created during the yarn preparation stage:

- High-twist yarns are tightly twisted in either a single direction (S-twist or Z-twist) or alternately twisted, creating tension.

- This over-twisting gives the yarn elasticity and the ability to crinkle once woven or exposed to heat/moisture.

3. Weaving or Knitting

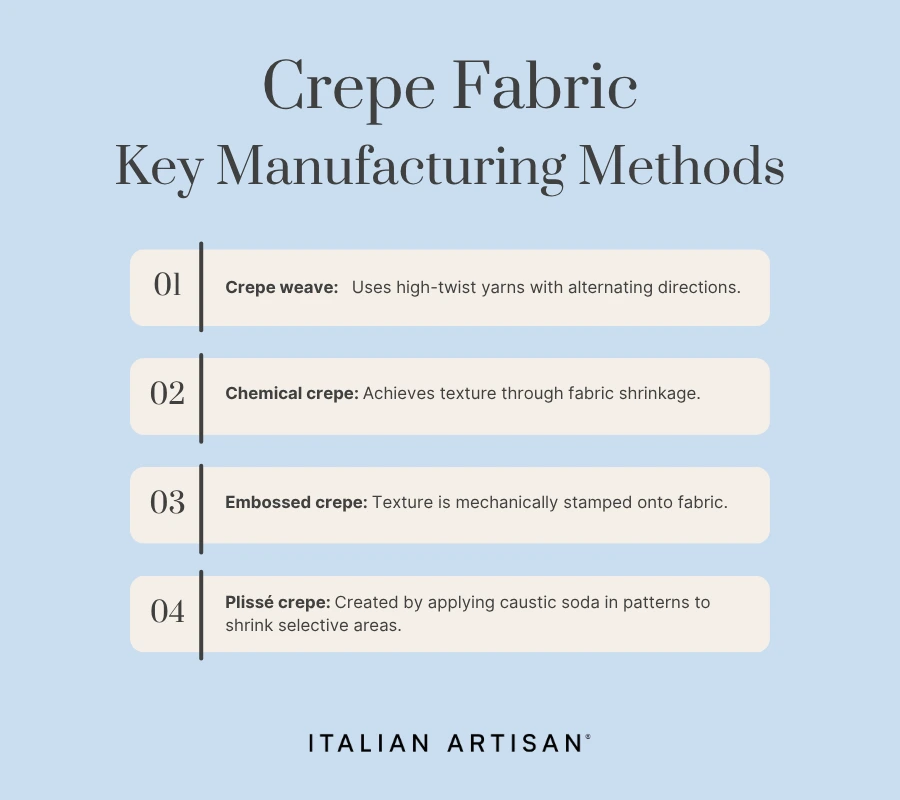

There are multiple ways to produce the crepe texture:

- Weaving: Most crepes are woven using plain, satin, or twill weaves, depending on the desired final look.

- Knitting: Less common, but some stretch crepes are knitted using similar high-twist yarns.

4. Texturing Process

After weaving or knitting, the fabric undergoes special treatments to bring out the crinkled texture:

- Heat-setting: For synthetic fibers, heat is applied to permanently set the twist.

- Chemical finishing: In some cases, treatments like caustic soda are used to shrink certain fibers and create texture.

- Embossing or calendaring (less common): Mechanical finishing techniques can also add a crepe-like texture.

5. Dyeing and Finishing

The final stage involves:

- Dyeing: Depending on the fiber type, crepe fabrics are dyed using appropriate methods (acid dyes for silk, disperse dyes for polyester, etc.).

- Finishing: The fabric may be softened, treated for wrinkle resistance, or given special finishes (e.g., anti-static, stain resistance).

Produce your fashion collection with us

Common Uses in Fashion

Crepe fabric is widely used in fashion for its elegant drape, soft texture, and versatility. It suits both structured and flowy designs, making it ideal across a range of garments:

- Dresses: Perfect for both daywear and evening gowns thanks to its fluid movement and flattering fit.

- Blouses & Tops: Offers comfort and polish, commonly used for workwear and casual-chic styles.

- Skirts: Especially popular in A-line and pencil cuts for a refined yet comfortable look.

- Trousers: Used in wide-leg or tapered styles—often with heavier crepes for added structure.

- Suits: Wool crepe is a favorite in women’s tailoring for its crisp finish and subtle texture.

- Scarves & Accessories: Lightweight silk or polyester crepes add softness and elegance.

- Bridal & Formalwear: Chosen for minimalist gowns, jumpsuits, and bridesmaid dresses for its smooth fall and understated luxury.

Understanding the Environmental Impact of Crepe Fabric

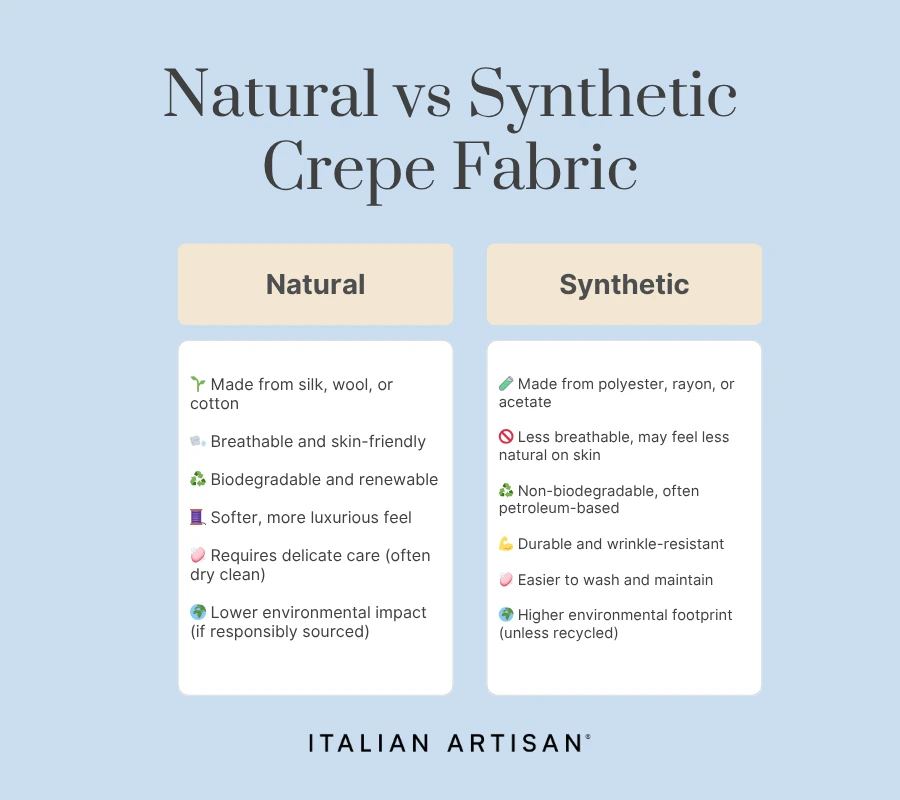

The environmental impact of crepe fabric depends largely on the fiber used to produce it. Since crepe refers to the fabric’s texture—not a specific material—it can be made from both natural fibers (like silk, cotton, or wool) and synthetic ones (such as polyester or rayon), each with different sustainability profiles:

- Natural fiber crepe (e.g., silk or cotton):

- Pros: Biodegradable, renewable, breathable

- Cons: Often resource-intensive (e.g., water use in cotton, ethical concerns in silk)

- Synthetic fiber crepe (e.g., polyester, rayon):

- Pros: Durable, cost-effective, low-maintenance

- Cons: Derived from petroleum, non-biodegradable (polyester), or chemically intensive (rayon)

Other environmental considerations include:

- Dyeing and finishing processes, which may involve chemicals and high water use.

- Microfiber pollution, especially with synthetic crepe washed frequently.

- End-of-life impact, as synthetic blends are harder to recycle or decompose.

Exploring Price Points and Value for Money

Crepe fabric is available across a wide range of price points, largely influenced by the type of fiber used, manufacturing process, and brand positioning. When assessing value for money, it’s important to consider both the material quality and the intended use:

- Natural fiber crepe (e.g., silk, wool, cotton):

Typically positioned as a premium option, offering superior drape, breathability, and a refined finish. Ideal for formalwear or luxury garments. - Synthetic or blended crepe (e.g., polyester, rayon):

More affordable and widely available, these versions are known for durability, wrinkle resistance, and low maintenance. Best suited for everyday wear and budget-conscious projects.

Key Value Considerations:

- Longevity: Synthetic crepe offers good durability for frequent use, while natural crepe stands out in comfort and elegance.

- Aesthetic Appeal: Silk and wool crepes provide a more luxurious look and feel, often justifying a higher investment.

- Ease of Care: Synthetic crepes require less upkeep, reducing long-term maintenance effort and cost.

- Purpose: Choose higher-end crepe for special occasions or timeless pieces; opt for practical blends for casual or seasonal fashion.

Conclusion

Crepe fabric is known for its distinctive crinkled texture, created through high-twist yarns, specific weaves, or chemical treatments. Unlike other fabrics, it’s defined by finish rather than fiber, and can be made from silk, wool, cotton, or synthetics like polyester and rayon. Its elegant drape, wrinkle resistance, and versatility make it popular in fashion, from dresses and blouses to suits and formalwear. The environmental impact of crepe varies: natural fibers are generally more sustainable, while synthetics may involve higher energy use and pollution. Choosing responsibly sourced materials helps balance the fabric’s aesthetic appeal with environmental responsibility.

FAQs

1. What is crepe fabric?

Crepe fabric is a textile known for its crinkled or pebbled texture, created through twisted yarns or chemical treatments. It’s valued for its fluid drape and elegant appearance.

2. Why is crepe fabric so popular in fashion?

Crepe is popular for its versatility, soft drape, and wrinkle resistance, making it ideal for both everyday wear and formal clothing.

3. What is crepe fabric made of?

Crepe can be made from various fibers, including silk, wool, cotton, polyester, and rayon. The fiber used affects the weight, feel, and properties of the fabric.

4. How is crepe fabric different from other fabrics?

Unlike smooth fabrics, crepe has a textured surface and a more fluid, graceful drape. It also resists wrinkles better than many flat-woven textiles.

5. What are the main properties of crepe fabric?

Key properties include a crinkled texture, soft drape, moderate stretch, wrinkle resistance, and suitability for both structured and flowing garments.

6. Where does crepe fabric originate from?

Crepe has origins in Europe and Asia, particularly in France and Japan, where different techniques developed to create its unique texture.

7. Is crepe fabric breathable?

Yes—if made from natural fibers like cotton or silk. Synthetic crepes may be less breathable but are often more durable and easier to care for.

8. Will crepe fabric shrink or stretch over time?

Crepe fabrics made from natural fibers may shrink slightly if not cared for properly. Synthetic crepes are generally more stable and stretch-resistant.

9. How do I care for crepe fabric clothing?

Care depends on the fiber: silk crepe requires delicate washing or dry cleaning, while polyester crepe is often machine-washable. Always check the label.

10. Is crepe fabric environmentally friendly?

It depends on the fiber and production process. Natural-fiber crepes are more eco-friendly, while synthetic versions may have a higher environmental impact.