2 – Banana Fabric Composition

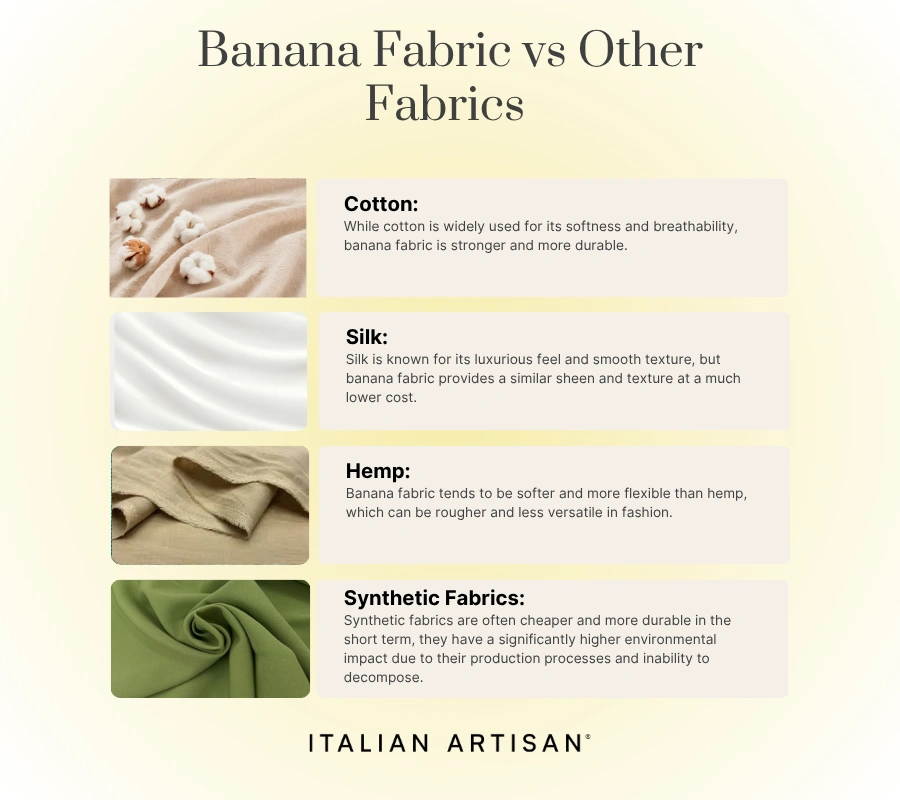

3 – Banana Fabric vs Other Fabrics

4 – Banana Fabric Is Manufactured

5 – Common Uses in Fashion

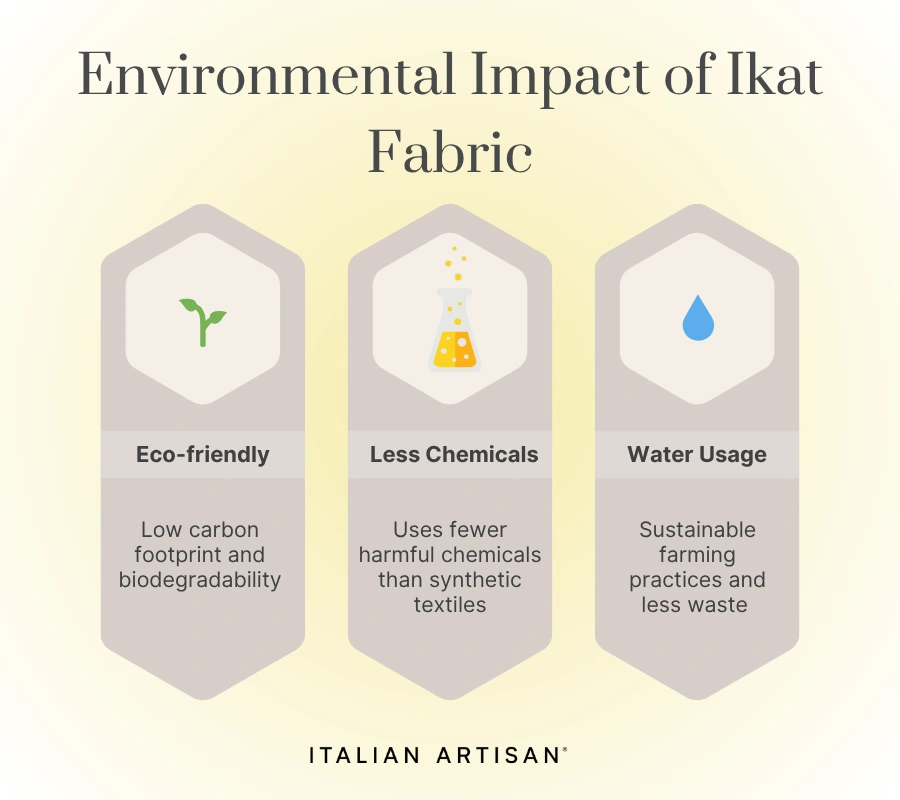

6 – Understanding the Environmental Impact of Banana Fabric

7 – Exploring Price Points and Value for Money

8 – Conclusion

9 – FAQs

What is Banana Fabric?

Banana fabric, also known as banana fiber, is a natural textile made from the stem of the banana plant, specifically from the pseudostems (the part of the plant that holds the fruit). Banana fabric has been used for centuries in countries like Japan, the Philippines, and Nepal for making clothing, accessories, and even paper. The fabric is praised for its eco-friendly qualities, strength, and unique texture, making it a sustainable alternative to traditional fibers like cotton and silk.

What makes Banana fabric unique is its composition and natural production process. Unlike other fabrics made from cotton or flax, banana fiber is produced by extracting fibers from the plant’s stem, which would otherwise be discarded. This process involves harvesting the banana plants, separating the fibers, and spinning them into yarn. The resulting fabric is biodegradable, lightweight, and breathable, with a texture that resembles linen or silk.

Key characteristics of Banana fabric include:

- Sustainability: Made from renewable resources, banana fabric is an eco-friendly choice, requiring minimal chemicals in production.

- Strength and Durability: Despite being lightweight, banana fiber is incredibly strong and resistant to wear.

- Softness and Texture: The fabric has a unique texture that is soft yet durable, often compared to linen, and can be dyed easily.

- Breathability: Like other natural fibers, banana fabric is breathable, making it ideal for warm-weather clothing.

Banana fabric is gaining recognition in the fashion industry as a sustainable alternative to more common materials. Its growing popularity can be attributed to the increasing demand for eco-friendly fabrics and sustainable production practices.

Banana Fabric Origin

Banana fabric, derived from the pseudostems of banana plants, has a long history in Asia, particularly in Japan, the Philippines, and Nepal. It was traditionally used for clothing, ropes, and paper. In these regions, the banana plant is abundant, and the pseudostem, once the fruit is harvested, was repurposed into strong, durable fibers.

Historically, in the Philippines, the fiber, called abacá, was used for lightweight clothing, while in Japan, it was woven into garments like kimonos. Today, banana fabric is gaining global attention as a sustainable alternative, especially in the fashion and eco-friendly product markets.

- Origins in Asia, used in traditional garments and other products.

- Resurging globally due to its sustainability.

Banana fabric’s rich history makes it an appealing choice for modern sustainable fashion.

Banana Fabric Composition

Banana fabric is primarily composed of fibers extracted from the pseudostem of the banana plant. The fibers are long, strong, and flexible, which makes them ideal for weaving into textiles. The process involves harvesting the banana plant, stripping away the outer layers to reveal the fiber-rich inner part of the stem, and then extracting the fibers through a mechanical or chemical process.

The composition of banana fiber is mainly cellulose, which gives it strength and durability. Depending on the processing method, banana fibers can vary in texture—from coarse to fine—allowing for different fabric finishes. The fibers are then spun into yarn and woven or knitted into fabric.

Banana fabric is known for being:

- Strong and durable: Despite being lightweight, the fibers are tough and resistant to wear.

- Biodegradable: Since it’s made from plant-based cellulose, banana fabric is fully biodegradable.

- Soft yet textured: It has a natural texture that resembles linen, offering both softness and strength.

Banana Fabric vs Other Fabrics

Banana fabric stands out among other natural fibers due to its unique combination of strength, texture, and sustainability. Here’s how it compares to some common fabrics:

- Banana Fabric vs Cotton: While cotton is widely used for its softness and breathability, banana fabric is stronger and more durable. It also offers a more textured feel, similar to linen, making it ideal for a variety of fashion and home textiles. However, cotton is often cheaper and more widely available.

- Banana Fabric vs Silk: Silk is known for its luxurious feel and smooth texture, but banana fabric provides a similar sheen and texture at a much lower cost. Banana fabric is also more durable and eco-friendly, as it’s made from plant fibers, whereas silk is derived from silkworms.

- Banana Fabric vs Hemp: Hemp shares some sustainable benefits with banana fabric, as both are natural fibers with low environmental impact. However, banana fabric tends to be softer and more flexible than hemp, which can be rougher and less versatile in fashion.

- Banana Fabric vs Synthetic Fabrics: Unlike synthetic fabrics like polyester, banana fabric is biodegradable and made from renewable resources. While synthetic fabrics are often cheaper and more durable in the short term, they have a significantly higher environmental impact due to their production processes and inability to decompose.

How Banana Fabric Is Manufactured

The manufacturing process of banana fabric is a fascinating one that begins with the banana plant and ends with a sustainable, eco-friendly textile. Here’s an overview of how Banana fabric is produced:

- Harvesting the Banana Plant: The process begins by harvesting the banana plant, specifically the pseudostem, which is the part of the plant that holds the fruit. This is typically a byproduct of banana farming, which would otherwise be discarded.

- Extracting the Fibers: The pseudostem is peeled to reveal the inner layers rich in fibers. These fibers are separated using a process that can be either mechanical (manual stripping) or chemical (using solutions to dissolve the non-fibrous material).

- Spinning the Fibers: After the fibers are extracted, they are cleaned and spun into yarn. The fibers can be processed in different ways, from coarse to fine, depending on the desired texture of the fabric.

- Weaving or Knitting: The yarn is then woven or knitted into fabric. This is where the texture and finish of the fabric are determined, ranging from smooth to textured, resembling linen or silk.

- Finishing: The fabric may undergo further treatments to enhance its appearance, such as dyeing, softening, or adding special finishes for durability or water resistance.

Produce your fashion collection with us

Common Uses in Fashion

Banana fabric, with its strength, eco-friendliness, and natural texture, is becoming increasingly popular in various fashion and textile applications. Here are some of its common uses:

- Clothing: Banana fabric is used in the creation of lightweight, breathable clothing such as shirts, dresses, skirts, and trousers. Its soft yet durable texture makes it ideal for summer wear and casual outfits.

- Accessories: The fabric is also used to make accessories like scarves, hats, and bags. Its natural sheen and texture give these items a unique, handcrafted feel.

- Home Textiles: Banana fabric is sometimes used in home furnishings, such as curtains, upholstery, and cushion covers. Its strength and elegant appearance make it a great option for eco-friendly interior designs.

- Traditional Garments: In regions where banana fabric has been used for centuries, such as Japan and the Philippines, it is still used to create traditional garments like sarongs and wraps, often valued for its cultural significance and sustainable qualities.

- Eco-Friendly Fashion: As the fashion industry embraces sustainability, Banana fabric is increasingly being incorporated into eco-conscious fashion lines. Its biodegradable nature and low environmental impact make it a great choice for green fashion brands.

Understanding the Environmental Impact of Banana Fabric

Banana fabric is an eco-friendly alternative to many traditional textiles, offering several environmental benefits:

- Low Carbon Footprint: Made from natural plant fibers, it has a smaller carbon footprint than synthetic fabrics.

- Biodegradable: As a cellulose-based fabric, it decomposes naturally, unlike synthetic fabrics that persist for centuries.

- Minimal Water Usage: Banana plants require less water compared to cotton, making it a more sustainable choice.

- Sustainable Farming: The pseudostem of the banana plant is a byproduct, reducing waste in banana farming.

- Fewer Chemicals: Banana fabric production uses fewer harmful chemicals than synthetic textiles.

Exploring Price Points and Value for Money

Banana fabric is a relatively affordable option compared to high-end natural fabrics like silk, but its price can vary depending on factors such as quality, production methods, and market availability. Here’s a breakdown of what influences the price of Banana fabric:

- Production Costs: The process of harvesting the banana plant, extracting fibers, and spinning them into yarn can be labor-intensive, especially in small-scale or traditional production methods. However, as demand grows and production methods become more efficient, costs are expected to decrease.

- Eco-Friendly Premium: As a sustainable fabric, Banana fabric may come with a slightly higher price than conventional cotton or polyester due to its environmentally friendly production methods and the use of renewable resources. However, it still tends to be more affordable than luxury fabrics like silk.

- Quality and Finish: The price can also vary depending on the finish and texture of the fabric. Higher-quality Banana fabrics with refined textures or added finishes (like softening or dyeing) will generally be more expensive.

- Market Demand: Banana fabric is still relatively niche, and its price can fluctuate based on supply and demand. As it becomes more popular in eco-conscious fashion markets, the price may become more competitive.

Conclusion

Banana fabric is an eco-friendly, durable alternative to traditional fabrics like cotton and silk. Made from the pseudostem of the banana plant, it offers strength, biodegradability, and minimal environmental impact, making it ideal for sustainable fashion.

While it may be slightly more expensive than conventional fabrics, Banana fabric provides excellent value, offering a luxurious feel at a lower cost than silk.

- Eco-friendly and biodegradable, it’s a sustainable choice for fashion.

- Durable and affordable compared to luxury fabrics like silk.

- Versatile and gaining popularity as a sustainable alternative.

Banana fabric is a strong contender for those seeking both luxury and sustainability in their clothing choices.

FAQs

1. What is Banana fabric made of?

Banana fabric is made from the pseudostem of the banana plant, which is processed to extract strong, durable fibers.

2. How is Banana fabric different from cotton?

While both are natural fibers, Banana fabric is stronger, more durable, and has a unique texture that resembles linen, whereas cotton is softer but less durable.

3. Is Banana fabric eco-friendly?

Yes, Banana fabric is biodegradable, requires minimal water, and is made from a renewable resource, making it a sustainable alternative to synthetic fabrics.

4. How is Banana fabric produced?

The fibers are extracted from the banana plant’s pseudostem, spun into yarn, and woven or knitted into fabric.

5. Is Banana fabric as durable as silk?

Yes, Banana fabric is strong and durable, offering a similar luxurious feel to silk at a more affordable price.

6. Can Banana fabric be dyed?

Yes, Banana fabric can be dyed, and it takes color well, allowing for a variety of finishes and designs.

7. Is Banana fabric expensive?

It is generally more affordable than silk but may be slightly more expensive than cotton or polyester due to its eco-friendly production process.

8. How should Banana fabric be cared for?

Banana fabric should be hand-washed or machine-washed on a gentle cycle in cold water, and air-dried to maintain its texture and durability.

9. Can Banana fabric be used in all types of clothing?

Yes, it is versatile and can be used for dresses, shirts, scarves, bags, and even home textiles like curtains and upholstery.

10. Is Banana fabric biodegradable?

Yes, Banana fabric is biodegradable, making it a more sustainable option compared to synthetic fibers.