2 – The Craftsmanship Behind Italian Production

3 – The Cost of Raw Materials

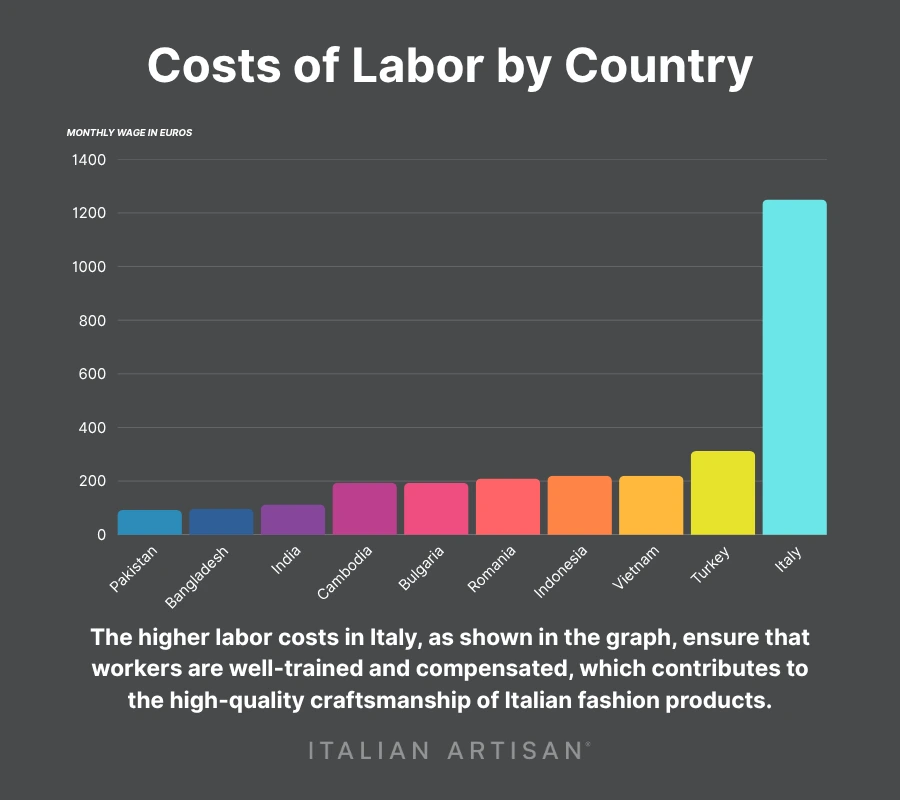

4 – The Costs of Labor and Time

5 – The High Cost of Electricity in Italy

6 – Ensuring Authenticity in ‘Made in Italy’ Products

7 – Italian Artisan: Connecting Brands with Authentic Manufacturers

8 – Conclusion

9 – FAQs

Introduction

When we think of luxury and craftsmanship, “Made in Italy” quickly comes to mind. From high-end fashion to premium leather goods, Italy has long been recognized for producing some of the world’s finest products. But the higher price tags of Italian-made goods come with more than just the label – they reflect the quality of materials, the expertise of artisans, the rich tradition of design, and the authenticity of every piece.

In this article, we’ll explore the true costs behind “Made in Italy” products, uncovering the factors that contribute to their premium prices. From the skill of artisans and sustainable sourcing to the sophisticated design and production processes, “Made in Italy” is not just a label, but a symbol of excellence – with real costs that justify the premium.

The Craftsmanship Behind Italian Production

Italian manufacturing is synonymous with exceptional craftsmanship. Every step, from design to production, is handled by skilled artisans who have refined their craft over generations. Here’s a closer look at the key elements:

- Skilled Artisans: Many Italian manufacturers are family-owned businesses with centuries of expertise. For instance, leatherworkers in Florence are renowned for their ability to create the finest leather goods, a skill developed over years of training.

- Handmade Precision: A significant portion of Italian production is done by hand, from stitching to assembling. While this process requires more time and labor, it results in a level of quality and detail that cannot be replicated by machines. High-end brands often insist on Italian craftsmanship for its unique value.

- Attention to Detail: Every item goes through rigorous quality control, ensuring precision at every stage. The meticulous finish is what makes Italian-made products stand out, often outlasting cheaper alternatives.

The Cost of Raw Materials

Italy is well known for sourcing some of the finest raw materials in the world, and this plays a critical role in driving up production costs.

- Premium Leather: Italy boasts world-class tanneries, especially in Tuscany, where vegetable-tanned leather is a hallmark of craftsmanship. The complex and time-consuming tanning process adds value, making the leather durable and aesthetically appealing.

- Silk and Textiles: Italian silk, particularly from Como, is regarded as some of the finest in the world. The intricate weaving and dyeing techniques involved ensure that Italian textiles not only look stunning but also possess remarkable strength and longevity.

- Sustainable Sourcing: Italy is increasingly committed to sustainable manufacturing. Many Italian manufacturers prioritize eco-friendly materials and support for local farmers, making sustainability a core part of the production process. While sustainable practices often come at a premium, they ensure that Italian products meet the growing demand for ethical goods.

The Costs of Labor and Time

Labor is another significant contributor to the higher cost of Italian products. The average labor cost in Italy is around €27.50 per hour, which is much higher than in countries like Portugal (€16.10/hour), Turkey (€5/hour), or China (€6/hour). These higher wages reflect Italy’s strong labor laws, better working conditions, and worker protections, which ultimately add to the cost of production.

- Sustainability and Fair Wages: Italian manufacturers also prioritize fair wages and safe working conditions. This commitment to ethical labor practices is embedded in the “Made in Italy” ethos and adds to the overall cost but also supports the integrity of the production process.

- Skilled Labor: Artisans with years of training and experience ensure high-quality products, which often come with higher labor costs. However, it’s important to note that not all manufacturers in Italy adhere to the same standards, and some may rely on automation that doesn’t always match the craftsmanship of skilled labor.

- Longer Production Time: Italian products are often produced more slowly than mass-produced alternatives. The deliberate crafting of a luxury handbag or hand-stitched leather jacket can take months, which contributes to both higher costs and longer lead times.

Produce your fashion collection with us

The High Cost of Electricity in Italy

An important but often overlooked factor in Italy’s manufacturing costs is the high price of electricity. In late 2024, Italy’s industrial electricity costs averaged €0.2151 per kWh, significantly higher than the EU average of €0.1899 per kWh. This disparity is primarily due to Italy’s energy mix, which still relies heavily on imported fossil fuels despite efforts to expand renewable sources.

Electricity is essential for energy-intensive processes like leather tanning, textile production, and the operation of machinery. These higher energy costs contribute to the overall production costs, often being passed on to consumers. However, this is also part of what makes Italian manufacturing stand out – manufacturers in Italy often invest in energy-efficient technologies and sustainable energy practices, which help mitigate some of the impact of high electricity prices.

Ultimately, while these higher energy costs do contribute to the price of Italian products, they also align with Italy’s commitment to high-quality, sustainable production.sustainable practices to the meticulous processes that make Italian products some of the finest in the world.

Ensuring Authenticity in ‘Made in Italy’ Products

One of the biggest challenges in Italian manufacturing is the issue of counterfeit “Made in Italy” goods. Due to legal loopholes, products made in factories that often rely on Chinese labor can still carry the “Made in Italy” label. These factories, located in areas like Prato and Florence, may replicate Italian designs but lack the traditional craftsmanship that defines authentic Italian products.

These counterfeit goods not only undermine Italy’s rich manufacturing heritage but also mislead consumers. Legal loopholes allow products with minimal Italian involvement to be labeled as “Made in Italy,” making it harder for brands to differentiate between genuine craftsmanship and subpar production.

- Quality Varies: Just because a product is labeled “Made in Italy” doesn’t automatically mean it’s of superior quality. Quality depends on the manufacturer’s commitment to craftsmanship, materials, and ethical practices. Brands must carefully vet their manufacturing partners to ensure they’re working with trusted producers.

Italian Artisan: Connecting Brands with Authentic Manufacturers

Navigating the complexities of Italian manufacturing—finding skilled artisans, managing timelines, and Finding reliable, authentic manufacturers in Italy can be challenging, especially for brands outside the country. Platforms like Italian Artisan make this process easier by providing access to a curated network of skilled Italian manufacturers.

- Sustainability and Transparency: Italian Artisan emphasizes sustainable production practices and transparency. The platform works with manufacturers that prioritize ethical sourcing and environmentally friendly methods, so brands can be assured of the integrity of their Made in Italy products.

- Vetted Network: Italian Artisan partners with only the best manufacturers across Italy, ensuring that brands can confidently produce high-quality products. Whether you need leather goods, clothing, or accessories, Italian Artisan connects you with trusted experts.

- Tailored Services: Italian Artisan works closely with brands to understand their specific production needs, from technical specifications to final delivery. The platform offers comprehensive support throughout the process, ensuring the best outcome for every project.

Conclusion

The true costs of Made in Italy extend far beyond premium price tags. They encompass elevated labor wages, higher raw material costs, and substantial electricity expenses. However, significant issues such as inconsistent quality, labeling loopholes, and the troubling reality of counterfeit Made in Italy products should also inform any decision to produce in Italy.

Brands must approach Italian production critically and strategically, thoroughly evaluating potential manufacturing partners rather than relying on a romanticized image. By collaborating with reliable platforms such as Italian Artisan, brands can mitigate these risks, accessing genuinely authentic and transparent Made in Italy manufacturing.

FAQS

Why is Made in Italy more expensive than other manufacturing?

Made in Italy products are more expensive due to the high-quality materials, skilled labor, time-intensive processes, and ethical labor standards involved. The attention to detail, craftsmanship, and lasting value of Italian-made products set them apart from mass-produced alternatives.

Are all Italian products made by hand?

Not all, but many Italian products, particularly in luxury goods, are crafted by hand. This handcrafted approach ensures superior quality and attention to detail, which is difficult to replicate in mass production.

How can I find reliable Made in Italy manufacturers?

Platforms like Italian Artisan provide access to a carefully vetted network of skilled Italian manufacturers. By partnering with such platforms, brands can ensure that they are working with trusted artisans and manufacturers to produce high-quality products.

What types of products are best to produce in Italy?

Italy is renowned for producing luxury leather goods, fashion, textiles, shoes, and accessories. Additionally, Italian craftsmanship extends to high-end furniture, jewelry, and many other luxury goods, benefiting from the country’s rich tradition of quality and design.

Why is labor in Italy more expensive than in other countries?

Italian labor is more expensive because artisans and workers are highly skilled, and the production process is often slow and meticulous. Italian manufacturers also prioritize fair wages and working conditions, which contributes to higher costs. The level of craftsmanship and attention to detail requires more time and expertise, which drives up the cost.

What impact does Italy’s electricity cost have on manufacturing?

Italy has some of the highest electricity costs in Europe, which increases operational expenses for manufacturers. High electricity prices can directly affect production costs, especially for energy-intensive industries like fashion manufacturing. This added expense often gets passed on to consumers in the form of higher prices for Italian-made products.

How do Italian manufacturers ensure sustainability in their production?

Many Italian manufacturers prioritize sustainability by using eco-friendly materials, reducing waste, and ensuring ethical sourcing. By investing in sustainable practices, they not only produce high-quality goods but also minimize the environmental impact of production.

Is it worth investing in Made in Italy products for my brand?

Yes, investing in Made in Italy products can be a smart decision for brands seeking high-quality, durable, and luxury products. The unique combination of craftsmanship, premium materials, and design expertise results in items that stand out in the market, often yielding higher customer satisfaction and brand prestige.

How long does it take to produce Made in Italy items?

The production timeline for Made in Italy items can vary depending on the complexity of the product. Simple items may take a few weeks, while more intricate and luxury pieces may take several months. Quality control and attention to detail often require more time than mass production.

How does Italian Artisan help brands produce in Italy?

Italian Artisan provides a platform for brands to connect with experienced manufacturers across Italy. With a focus on quality, sustainability, and transparency, the platform ensures that brands can create premium Made in Italy products by collaborating with trusted artisans and manufacturers. The service is tailored to fit specific production needs, ensuring a smooth and efficient process.