2 – Cupro Fabric Composition

3 – Cupro Fabric vs Other Fabrics

4 – How Cupro Fabric Is Manufactured

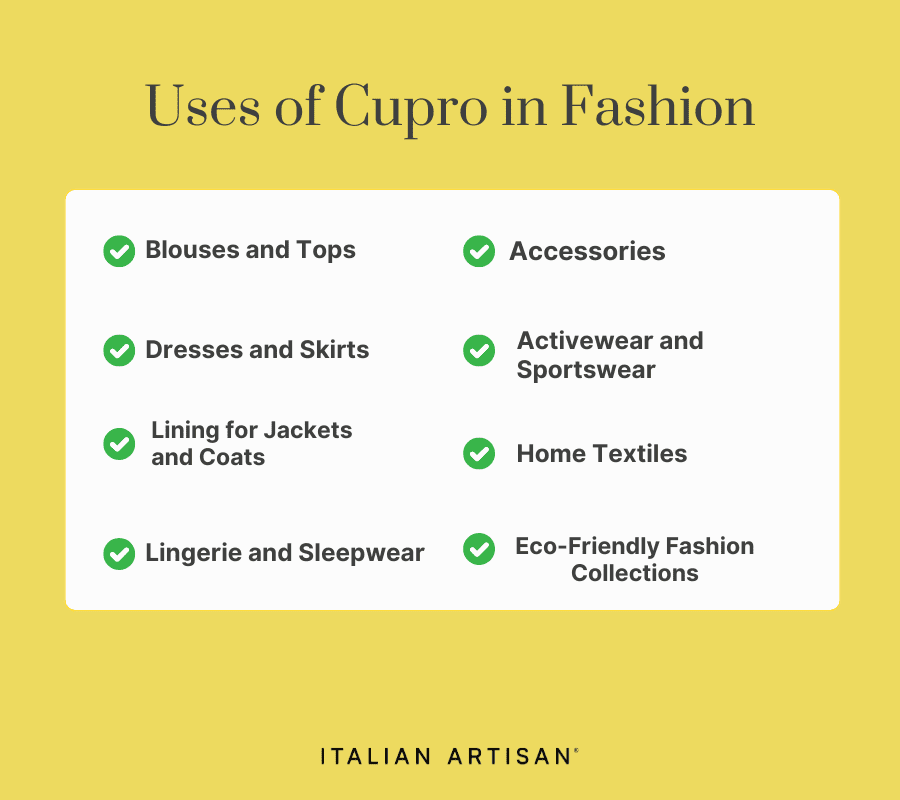

5 – Common Uses in Fashion

6 – Understanding the Environmental Impact of Cupro Fabric

7 – Exploring Price Points and Value for Money

8 – Conclusion

9 – FAQs

What is Cupro Fabric?

Cupro fabric is a sustainable, semi-synthetic textile made from cotton linter, the by-product of cotton harvesting. Similar to rayon and Tencel, it stands out for its silky feel, breathability, and eco-friendly production. Originating in Japan, Cupro is made by breaking down cotton linter into cellulose, which is then reconstituted into fibers. Its production uses less water and chemicals than traditional cotton processing, making it a more sustainable option.

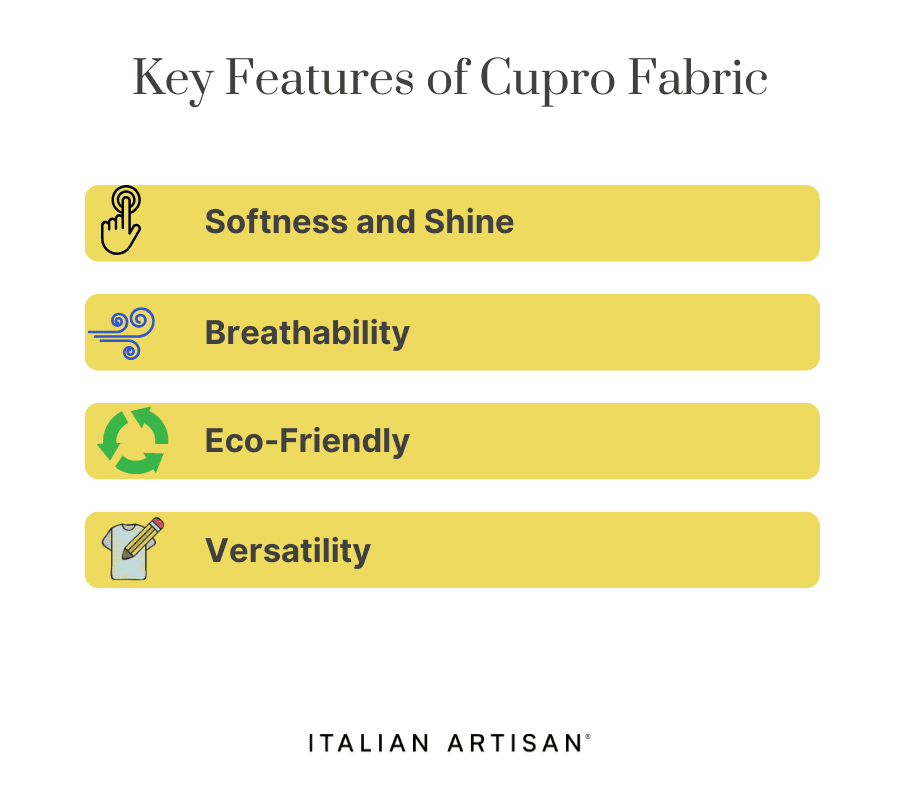

Key Features of Cupro Fabric

- Softness and Shine: Known for its smooth, silk-like texture and reflective sheen, making it a favorite for high-end fashion.

- Breathability: Cupro allows air to flow freely, making it comfortable for warm weather and ideal for garments like blouses and dresses.

- Eco-Friendly: Made from cotton linter, a by-product of cotton farming, Cupro offers a sustainable alternative to other textiles by reducing waste and minimizing resource consumption.

- Versatility: This fabric is used in a variety of applications, from luxurious garments to linings and even home décor, offering both aesthetic appeal and functionality.

Cupro fabric’s combination of sustainability and premium quality has made it an attractive option for fashion designers and eco-conscious consumers alike. It offers a perfect balance between performance, luxury, and environmental impact, making it a fabric to watch in the future of sustainable fashion.

Origin and History of Cupro Fabric

Cuprofabric was developed in Japan in the mid-20th century by Asahi Kasei to create a sustainable textile from cotton linter, a by-product often discarded in cotton production. The process involves chemically converting cotton linter into regenerated cellulose fibers, similar to rayon and Tencel. Unlike synthetic fabrics, cupro is made from plant-based waste, making it a more sustainable alternative. Its ability to be recycled at the end of its life further supports its eco-friendly profile. Cupro’s Japanese origins emphasize high-quality standards, and its use has grown among designers focused on both style and sustainability.

Cupro Fabric Composition

Cupro fabric is primarily composed of cellulose, a natural polymer found in plant cell walls, most notably derived from cotton linter, the short fibers left behind after cotton fibers are removed. The composition of cupro is similar to other regenerated fibers like rayon and Tencel, but it stands out due to its use of cotton by-products, making it a more sustainable option compared to materials like polyester or nylon.

The process of turning cotton linter into cupro fabric involves the following steps:

- Extraction of Cotton Linter:

Cotton linter is a by-product of cotton farming that is often discarded. After cotton is harvested and the long cotton fibers are separated, the remaining short fibers (linter) are collected. - Chemical Processing:

These fibers are then broken down into cellulose through a chemical process that dissolves the cotton linter into a soluble form. This process is similar to the production of other regenerated fibers, such as rayon. - Regeneration into Fibers:

The dissolved cellulose is then spun into fibers, which are later woven or knitted to form cupro fabric. The result is a soft, breathable, and versatile fabric that retains many of the beneficial properties of cotton. - Finishing:

After the fiber is spun, it is finished to give cupro its signature shine and smooth texture. The fabric often undergoes treatments to enhance its lustrous appearance and softness, making it resemble high-end fabrics like silk, but with the added benefits of being plant-based and sustainable.

Key Attributes of Cupro Fabric Composition Include:

- Natural cellulose base: Derived from cotton by-products, making it biodegradable and plant-based.

- Soft and silky texture: Due to the cellulose structure, cupro offers a luxurious feel, often likened to silk or satin.

- Eco-friendly production: The use of cotton linter minimizes waste, and the fabric can be recycled at the end of its life, supporting a more sustainable fashion industry.

Cupro Fabric vs Other Fabrics

When comparing cupro fabric to other textiles, it’s important to consider its unique balance of eco-friendliness, durability, and luxurious feel. Cupro occupies a niche between natural fibers and synthetics, offering distinct advantages over both. Here’s how cupro compares to other fabrics:

Cupro vs. Cotton

- Sustainability: While both are plant-based, cupro is made from cotton linter, a by-product that would typically be discarded, reducing waste. Cotton, on the other hand, requires significant water, pesticides, and land for cultivation.

- Feel and Texture: Cupro is softer and has a silky, shiny finish, while cotton is often more textured and less lustrous. Cupro is often compared to silk in terms of its luxurious feel.

- Breathability: Both fabrics are breathable, but cupro’s moisture-wicking properties make it more suitable for warm, humid conditions.

Cupro vs. Silk

- Feel and Appearance: Silk is a natural fiber with a beautiful shine and soft texture. However, cupro offers a similar luxurious feel and sheen but with the added benefit of being more affordable and sustainable.

- Care and Maintenance: Silk requires more delicate care, often needing dry cleaning or hand washing. Cupro is more durable and can usually be machine-washed on a gentle cycle, making it easier to maintain.

- Sustainability: While silk is a natural fiber, its production can be resource-intensive, with concerns over animal welfare and the use of chemicals in processing. Cupro, derived from cotton by-products, is a more sustainable alternative.

Cupro vs. Polyester

- Environmental Impact: Polyester is made from petroleum-based resources and is not biodegradable, leading to environmental concerns regarding plastic waste. Cupro, on the other hand, is biodegradable and made from cotton waste, making it a more eco-friendly option.

- Durability and Care: Polyester is highly durable and resistant to wrinkles, but it is less breathable than cupro. While cupro offers a more luxurious, breathable feel, polyester is easier to care for and more affordable.

- Texture and Aesthetic: Polyester tends to have a more synthetic feel and appearance, while cupro has a smooth, silk-like texture that feels more premium.

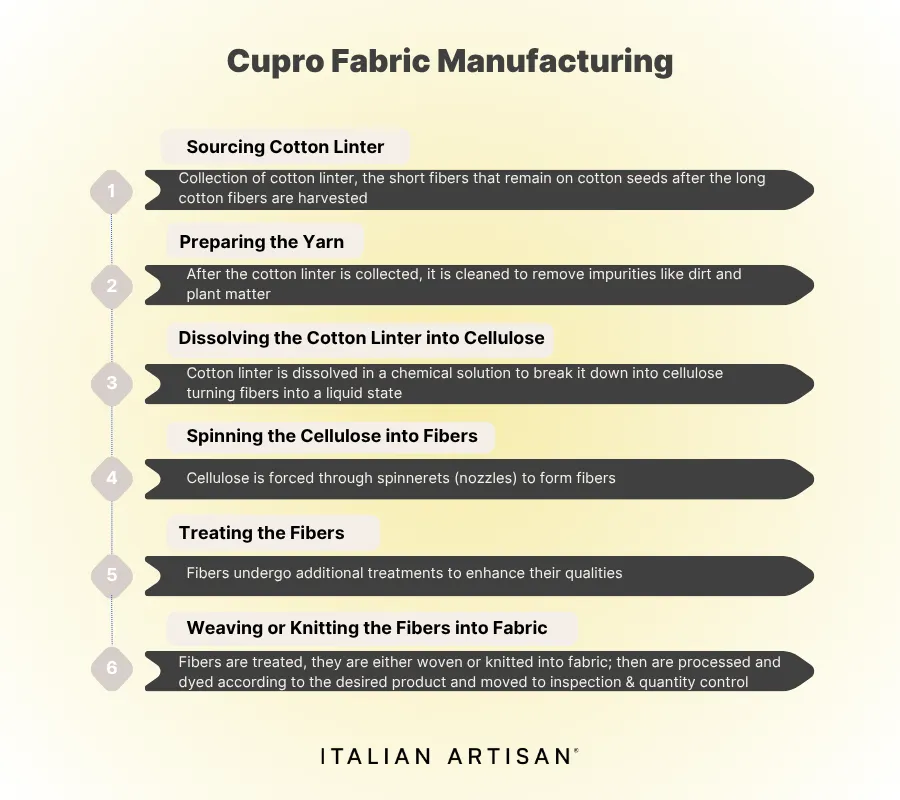

How Cupro Is Manufactured

The process of manufacturing cupro fabric is both fascinating and environmentally conscious, as it involves transforming cotton linter, a by-product of cotton farming, into a luxurious and eco-friendly textile. The production of cupro fabric follows several key stages that make it unique compared to other fabrics. Here’s a breakdown of how cupro is made:

- Sourcing Cotton Linter

The manufacturing process of cupro begins with the collection of cotton linter, the short fibers that remain on cotton seeds after the long cotton fibers are harvested. These fibers are often considered waste and are typically discarded. However, cupro fabric uses these cotton by-products, making it a more sustainable option by repurposing what would otherwise go to waste. - Cleaning and Preparing the Linter

After the cotton linter is collected, it is cleaned to remove impurities such as dirt and plant matter. The cleaned cotton linter is then broken down into a fine pulp. This is an essential step, as the pulp needs to be in its purest form for the next stage of the process. - Dissolving the Cotton Linter into Cellulose

The cotton linter is dissolved in a chemical solution to break it down into cellulose, the main component of plant fibers. This process transforms the cotton linter into a liquid state. While this step does involve chemicals, the process is relatively eco-friendly compared to other textiles like rayon, as it uses a closed-loop process that minimizes waste. - Spinning the Cellulose into Fibers

Once the cellulose is extracted, it is forced through spinnerets (similar to nozzles) to form fibers. These fibers are then solidified into long threads. The cellulose fibers created from this process have the same qualities as natural fibers like cotton, but they are much finer, which contributes to cupro’s soft, silky feel. - Treating the Fibers

The fibers undergo additional treatments to enhance their qualities. This may include finishing processes to add shine, improve softness, and give the fabric its smooth, luxurious texture. During this stage, the fibers may be bleached or dyed, depending on the desired color or appearance of the final product. - Weaving or Knitting the Fibers into Fabric

After the fibers are treated, they are either woven or knitted into fabric. The weaving process forms the fabric into sheets of material that can then be used to create garments and other products. This stage brings the fabric to life, allowing it to be shaped into everything from tops and dresses to accessories and linings. - Finishing and Dyeing

Cupro fabric may undergo further finishing processes to enhance its visual and tactile properties. These processes can include dyeing the fabric in various colors, giving it that distinctive sheen that makes cupro so desirable. The fabric can also be treated to improve its durability and ensure that the colors last longer. - Final Inspection and Quality Control

The final step involves inspecting the fabric for any imperfections and ensuring that it meets quality standards. This is crucial in maintaining the luxurious feel and high performance of cupro fabric. Once the fabric passes inspection, it’s ready to be cut, sewn, and used in fashion items, upholstery, or other textile products.

Produce your fashion collection with us

Common Uses in Fashion

Cupro fabric’s luxurious feel, breathability, and sustainable production process make it a versatile choice in the fashion industry. While it’s known for its silk-like texture and glossy finish, cupro is used in a variety of applications, offering both aesthetic appeal and practical benefits. Here are some of the most common uses of cupro fabric in fashion:

- Blouses and Tops

Cupro fabric is particularly popular for creating blouses and tops due to its soft texture and drape. The fabric’s smooth surface provides a polished, elegant look, making it ideal for both casual and formal occasions. It allows for comfortable wear throughout the day, offering breathability and moisture-wicking properties.

- Dresses and Skirts

The luxurious sheen of cupro fabric makes it a popular choice for dresses and skirts, where fluidity and movement are essential. It drapes beautifully, creating elegant silhouettes. Whether used in casual day dresses or more formal evening wear, cupro enhances the overall aesthetic while remaining comfortable and lightweight.

- Lining for Jackets and Coats

Due to its smooth texture and breathable nature, cupro is often used as lining for jackets, coats, and blazers. It provides a soft and breathable layer against the skin, ensuring comfort when wearing heavier outerwear. Additionally, cupro linings add a touch of luxury to garments without increasing the cost significantly.

- Lingerie and Sleepwear

Cupro’s softness and moisture-wicking abilities make it an excellent choice for lingerie and sleepwear. It feels gentle against the skin, which is ideal for garments worn close to the body. Its breathable properties also ensure comfort throughout the night, making it a popular fabric for pajamas and intimates.

- Accessories (Scarves, Shawls, and Handbags)

The smooth, glossy finish of cupro fabric makes it perfect for accessories such as scarves, shawls, and even handbags. Its lightness and flexibility allow it to be used in a variety of designs, offering both functionality and style. Cupro accessories provide a sophisticated, luxurious look that complements any outfit.

- Sustainable Activewear and Sportswear

While not as common as synthetic fabrics like polyester, cupro is starting to find its place in sustainable activewear and sportswear. Its moisture-wicking and breathable properties make it suitable for creating comfortable, functional sports clothing, including yoga pants and workout tops, that don’t compromise on style or environmental impact.

- Home Textiles (Cushion Covers, Curtains)

Beyond fashion, cupro fabric’s durability and sheen make it a great choice for home textiles. It’s used for creating stylish cushion covers, curtains, and upholstery, where its luxurious feel can elevate the décor. The fabric’s eco-friendly composition also makes it an appealing option for sustainable interior design.

- Eco-Friendly Fashion Collections

Many eco-conscious fashion brands have embraced cupro as part of their collections, using it for everything from everyday wear to high-end couture. Its sustainable production process and biodegradable properties align well with the growing demand for eco-friendly fashion. Designers looking to create sustainable yet stylish collections are increasingly turning to cupro fabric.

- Summer Fashion

Cupro’s lightweight and breathable nature makes it a go-to fabric for summer fashion. Tops, dresses, and skirts made from cupro are comfortable, cool, and stylish, making them perfect for warm weather. Its ability to wick away moisture and keep the body cool ensures that garments remain fresh throughout the day.

Understanding the Environmental Impact of Cupro Fabric

As the fashion industry becomes more focused on sustainability, understanding the environmental impact of materials like cupro fabric is essential. Cupro is often touted as an eco-friendly alternative to conventional fabrics, thanks to its unique production process and reliance on cotton linter—a by-product that would otherwise be discarded. Here’s a deeper look at how cupro fabric fares in terms of environmental sustainability:

1. Use of Cotton Linter: A Sustainable Resource

One of the key environmental benefits of cupro is its use of cotton linter, a cotton by-product that is typically considered waste. By repurposing this leftover cotton material, cupro helps reduce waste and makes use of a resource that would otherwise be discarded, rather than relying on virgin materials. This process significantly minimizes the environmental footprint of fabric production by recycling what would otherwise contribute to landfill waste.

2. Lower Water Usage Compared to Cotton

Traditional cotton farming requires large amounts of water, pesticides, and land, making it a resource-intensive crop. While cupro is made from cotton linter, which does not require the same extensive water usage as growing new cotton plants, it still benefits from the cotton industry’s established infrastructure. By using cotton linter, cupro helps minimize the environmental strain associated with cotton cultivation.

3. Eco-Friendly Production Process

The process of converting cotton linter into cupro fabric is relatively low-impact compared to the production of other fabrics like polyester or even rayon. Although it does involve a chemical process to break down the cellulose, cupro’s manufacturing process has been developed to be more environmentally friendly. Modern cupro production uses closed-loop systems that recycle water and solvents, minimizing pollution and waste. This efficient production method reduces energy consumption and prevents the release of harmful chemicals into the environment.

4. Biodegradability

Cupro fabric is biodegradable, which means that, unlike synthetic fabrics like polyester and nylon, it will break down naturally over time. This reduces its environmental impact at the end of its life cycle, helping to combat the growing issue of textile waste. When disposed of properly, cupro does not contribute to microplastic pollution, making it a far more environmentally friendly option than synthetic alternatives.

5. Energy Savings

The production of cupro fabric requires less energy compared to fabrics made from petroleum-based sources like polyester and nylon. By utilizing cotton linter, which is a renewable resource, the energy footprint of cupro is reduced, and the use of fossil fuels is minimized. Additionally, since cupro can be recycled into new fabric, the energy needed for producing new textiles is further reduced, supporting a circular economy.

6. Recyclability and Closed-Loop Potential

Cupro fabric supports a circular fashion model. The fabric is recyclable, meaning it can be broken down and reused in the future. Brands that use cupro in their collections can promote recycling programs, encouraging consumers to return worn-out garments for reuse. This closed-loop system aligns with the broader sustainable fashion movement, reducing the need for virgin raw materials and limiting waste.

7. Reduction of Synthetic Fibers

By choosing cupro over synthetic fibers like polyester or nylon, consumers can help reduce the production and use of petroleum-based materials. These synthetic fibers contribute to pollution, both during manufacturing and when they shed microplastics into the environment during washing. cupro, being made from plant-based cellulose, provides a biodegradable alternative that doesn’t contribute to microplastic contamination.

8. Sustainable End-of-Life

Beyond production, cupro fabric’s end-of-life sustainability is a significant benefit. Once garments made from cupro are no longer in use, they can be recycled or disposed of in an environmentally responsible manner. Unlike synthetic fabrics, which often sit in landfills for years, cupro’s biodegradability ensures it doesn’t contribute to long-term waste.

Exploring Price Points and Value for Money

When it comes to fabrics, cupro is often seen as a luxurious yet affordable option. While it’s priced higher than cotton, it’s still more affordable than fabrics like silk. Here’s why cupro offers great value for your money:

1. Price Range

Cupro typically costs between €15 and €50 per meter, depending on the quality and finish. While it’s more expensive than cotton, it’s a more affordable option than high-end fabrics like silk or satin. Cupro is considered a mid-range fabric, offering luxury without the hefty price tag.

2. Value for Money

Cupro fabric is a great investment for several reasons:

- Durability: Cupro is strong and long-lasting. Its ability to resist wear means you won’t have to replace garments as often, which saves money in the long term.

- Comfort: Cupro is breathable and moisture-wicking, keeping you cool and comfortable, especially in warm weather. This functionality makes it worth the price.

- Luxury Look: With a silky feel and a beautiful sheen, cupro offers a premium look and texture, like silk, but at a fraction of the price. For those seeking a luxurious fabric without the high cost, cupro is a smart alternative.

3. Cupro’s Value vs. Other Fabrics

- Cupro vs. Silk: While silk has a similar texture, it’s far more expensive and requires more care. Cupro gives you that same luxurious feel but is much easier to maintain and less costly.

- Cupro vs. Rayon: Rayon is a similar fabric, but it’s often made from wood pulp. Cupro is more sustainable, using cotton waste, making it a better choice for eco-conscious consumers.

- Cupro vs. Polyester: Polyester is cheaper, but it’s synthetic and harmful to the environment. Cupro is biodegradable and made from plant-based materials, offering a more sustainable option despite being a little more expensive.

4. Sustainable Choice for Long-Term Value

As demand for sustainable fashion grows, cupro’s price is expected to become more competitive. As more brands use it, the cost will likely go down, making it more affordable over time. It’s a wise investment for those who want high-quality, eco-friendly fashion that lasts.

5. Better for the Planet

In addition to its luxurious feel, cupro is biodegradable and made from cotton by-products, helping to reduce waste. It’s an excellent option for anyone looking to make more eco-conscious purchases without sacrificing style or quality.

Conclusion

Cupro fabric combines luxury, durability, and sustainability. Made from cotton linter, it offers a soft, breathable, and eco-friendly alternative to traditional fabrics. With its affordability and versatility, cupro is a smart choice for those seeking stylish, sustainable fashion.

FAQs

FAQs About Cupro Fabric

- What is Cupro fabric?

Cupro fabric is a luxurious, eco-friendly material made from cotton linter, a by-product of cotton farming. It’s soft, breathable, and often compared to silk.

- Where does Cupro fabric come from?

Cupro fabric was first developed in Japan, using cotton linter, which is a waste product from cotton processing.

- Who uses Cupro fabric?

Fashion brands that prioritize sustainability and luxury use Cupro fabric for creating stylish, eco-conscious garments and accessories.

- Why is Cupro fabric eco-friendly?

Cupro is made from cotton waste, which reduces textile waste. It’s also biodegradable, making it a more sustainable choice compared to synthetic fabrics.

- How is Cupro fabric made?

Cupro fabric is made by dissolving cotton linter into cellulose, which is then spun into fibers and woven or knitted into fabric.

- What are Cupro fabric properties?

Cupro fabric is soft, breathable, moisture-wicking, and has a luxurious sheen. It’s durable, comfortable, and resistant to wrinkles.

- How does Cupro fabric compare to silk?

Cupro has a similar texture and shine to silk but is more affordable and easier to maintain, making it a great alternative.

- Will Cupro fabric shrink after washing?

Cupro fabric may shrink slightly, so it’s recommended to wash it on a gentle cycle with cold water and air dry to maintain its shape.

- Why should I choose Cupro fabric over other materials?

Cupro offers the luxury of silk at a lower cost and is more sustainable than synthetic fabrics, making it a great choice for eco-conscious consumers. - How does Cupro fabric compare to cotton?

While cotton is breathable, Cupro is softer and has a more luxurious finish, providing a silk-like feel with similar comfort.